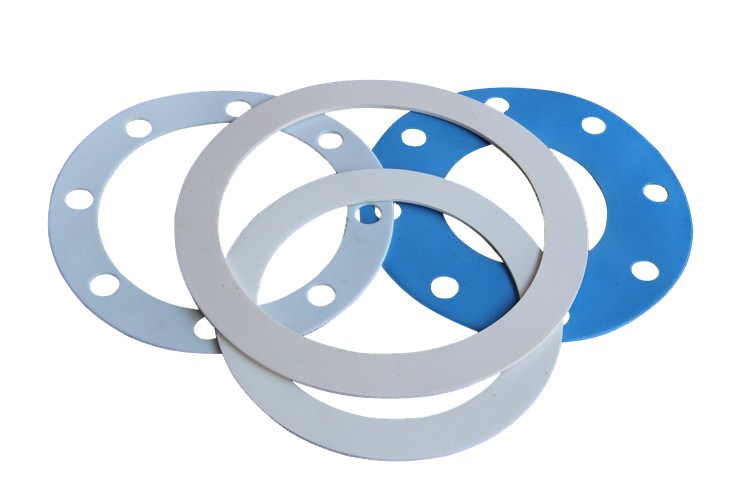

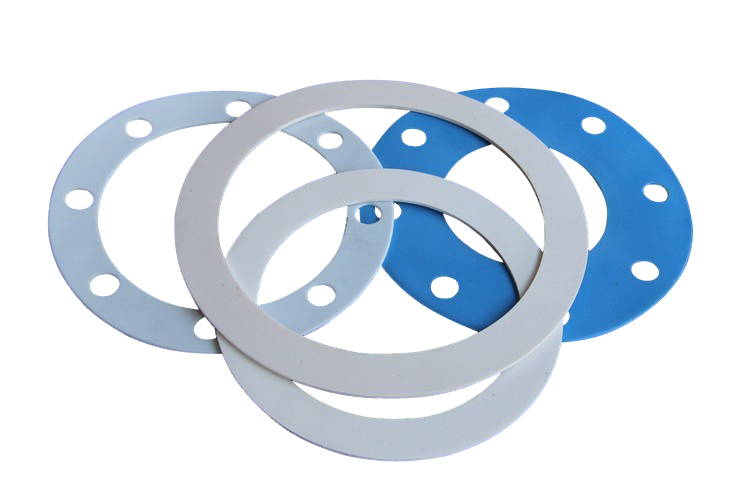

Modified PTFE Gasket

A modified PTFE gasket, also known as a modified polytetrafluoroethylene gasket, is a type of sealing gasket made from a modified version of PTFE (polytetrafluoroethylene) material. Modified PTFE gaskets are designed to provide enhanced sealing performance compared to standard PTFE gaskets, especial......

Send Inquiry

Product Description

A modified PTFE gasket, also known as a modified polytetrafluoroethylene gasket, is a type of sealing gasket made from a modified version of PTFE (polytetrafluoroethylene) material. Modified PTFE gaskets are designed to provide enhanced sealing performance compared to standard PTFE gaskets, especially in applications where chemical resistance, temperature resistance, and compressibility are critical factors. Here are some key characteristics and information about modified PTFE gaskets:

1. Material Composition: Modified PTFE gaskets are made from PTFE material that has been modified or enhanced with fillers, additives, or other materials to improve its properties and performance. The modifications are aimed at addressing the limitations of standard PTFE, such as its lack of compressibility and cold flow resistance.

2. Enhanced Compressibility: One of the primary advantages of modified PTFE gaskets is their improved compressibility compared to standard PTFE. This allows them to create a tighter seal when subjected to compressive loads, making them effective in applications with uneven or irregular sealing surfaces.

3. Temperature Resistance: Modified PTFE gaskets retain the excellent temperature resistance of standard PTFE, with the ability to withstand extremely high and low temperatures. They are often used in applications involving cryogenic temperatures up to high-temperature environments.

4. Chemical Compatibility: Modified PTFE gaskets are highly resistant to a wide range of chemicals, acids, bases, solvents, and corrosive substances. They are well-suited for use in aggressive chemical environments.

5. Low Friction: Like standard PTFE, modified PTFE gaskets exhibit low friction properties, making them suitable for dynamic sealing applications.

6. Sealing Applications: Modified PTFE gaskets are used in various industries, including chemical processing, pharmaceuticals, petrochemicals, food and beverage, and semiconductor manufacturing. They are commonly used in flange connections, heat exchangers, pumps, valves, and other equipment requiring a reliable and chemically resistant seal.

7. Dimensional Stability: Modified PTFE gaskets offer excellent dimensional stability, meaning they maintain their shape and sealing properties over time, even under temperature fluctuations and compression cycles.

8. Non-Stick Properties: Like standard PTFE, modified PTFE gaskets are non-stick and exhibit low adhesion properties, reducing the risk of gasket sticking to sealing surfaces.

9. FDA and NSF Compliant: Some modified PTFE gaskets are compliant with FDA (U.S. Food and Drug Administration) and NSF (National Sanitation Foundation) standards, making them suitable for use in food and pharmaceutical applications.

10. Installation: Proper installation procedures, including torque recommendations and ensuring clean and well-prepared sealing surfaces, are essential for achieving an effective and leak-free seal with modified PTFE gaskets.

When selecting a modified PTFE gasket for a specific application, consider factors such as temperature range, chemical compatibility, pressure requirements, and the nature of the sealing surfaces. Proper installation and adherence to manufacturer recommendations are crucial for achieving reliable and effective sealing in critical applications.