Hanger Bolt Factories: Top Manufacturers in China

2026-01-07

In the world of manufacturing, China stands as a powerhouse, and its hanger bolt factories are no exception—they drive innovation and efficiency globally. As you delve into this exploration of top manufacturers, you'll discover how companies like Topfence are setting industry standards. In this blog, we'll uncover what makes these leaders stand out, offering insights that could transform your sourcing decisions. Get ready to be intrigued by the expertise and quality shaping this vital sector!

Leading Producers of Hanger Bolts in China

China has emerged as a powerhouse in the production of hanger bolts, with a competitive landscape that blends traditional craftsmanship and modern technology. The country's industrial hubs, particularly in provinces like Zhejiang and Jiangsu, host numerous manufacturers who have honed their skills in producing these versatile fasteners. These firms often prioritize quality control and precision engineering, ensuring that their bolts meet both domestic and international standards. For instance, some leading producers leverage advanced CNC machining and automated assembly lines to maintain consistency across large-scale production runs, which helps them cater to diverse industries such as furniture, automotive, and construction. This focus on innovation allows them to offer a wide range of hanger bolt types, tailored to specific applications, while keeping costs competitive.

Several companies stand out in this market due to their specialized expertise and robust supply chains. One notable producer, based in Shanghai, has gained recognition for its durable and corrosion-resistant hanger bolts, using high-grade stainless steel and zinc plating techniques. Another key player, operating from Guangdong, emphasizes custom solutions, working closely with clients to design bolts that meet unique specifications for load-bearing and environmental resistance. These producers often invest in research and development to improve thread designs and material compositions, which enhances the longevity and reliability of their products. By fostering strong relationships with raw material suppliers and logistics partners, they ensure timely delivery and reduce production bottlenecks, making them reliable partners in global supply chains.

In recent years, China's hanger bolt manufacturers have also embraced sustainability initiatives and digital integration to stay ahead. Some leading producers are adopting eco-friendly practices, such as using recycled materials and optimizing energy consumption in their factories. Additionally, they implement digital tools like IoT sensors and data analytics to monitor production quality in real-time, reducing defects and waste. This forward-thinking approach not only boosts efficiency but also aligns with global trends toward greener manufacturing. As a result, these producers are well-positioned to meet growing demand from both established markets and emerging sectors, reinforcing China's role as a key contributor to the global fastener industry.

Key Features of Quality Hanger Bolt Manufacturing

Another standout aspect of high-quality hanger bolt production is the meticulous attention to threading and design consistency. Manufacturers utilize state-of-the-art CNC machinery to achieve precise tolerances, resulting in bolts that fit perfectly with nuts and other components without compromising structural integrity. This level of detail not only enhances ease of installation but also reduces the risk of failure under load, setting these products apart from mass-produced alternatives that often sacrifice precision for speed.

Beyond technical specifications, leading hanger bolt producers prioritize innovation and customization to meet diverse application needs. They engage in continuous research to develop new features, such as enhanced grip patterns or eco-friendly coatings, while offering tailored solutions for specific projects. This forward-thinking approach ensures that customers receive versatile, high-performance fasteners that adapt to evolving industry standards, reinforcing the brand's reputation for excellence and reliability in a crowded market.

Innovation Trends in Chinese Hanger Bolt Factories

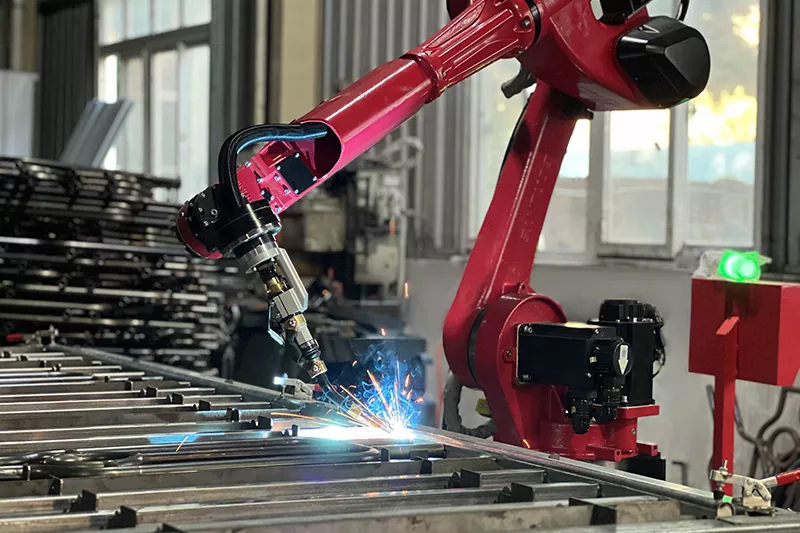

Chinese hanger bolt manufacturers are increasingly embracing automation and smart technologies to enhance production efficiency and product quality. Many factories now integrate AI-driven quality control systems and IoT sensors into their assembly lines, allowing for real-time monitoring and adjustments. This shift not only reduces human error but also enables customization at scale, catering to diverse global demands for specialized fasteners in construction and engineering projects.

A notable trend is the adoption of eco-friendly materials and sustainable practices, as factories invest in recycled alloys and energy-saving equipment to minimize environmental impact. This commitment extends to innovative design approaches, with some companies developing lighter, stronger hanger bolts that meet stringent international safety standards while reducing material waste. Such efforts position Chinese producers as leaders in the green manufacturing movement within the hardware sector.

Collaboration with research institutions and international partners is driving further innovation, leading to the creation of advanced coatings and corrosion-resistant finishes that extend bolt lifespans. By fostering a culture of continuous improvement and customer-focused R&D, these factories are transforming from traditional suppliers into agile innovators, ready to tackle evolving market challenges with cutting-edge solutions.

Customization Options for Global Clients

When working with clients around the world, we prioritize flexibility to meet diverse needs. Our approach goes beyond standard packages, allowing you to tailor solutions based on your region’s regulations, cultural nuances, and specific business goals. Whether it’s adjusting payment methods for local preferences or integrating regional data privacy laws, we ensure every detail fits seamlessly.

One of our standout features is the ability to customize user interfaces and workflows to reflect local languages and operational habits. For instance, clients in Asia might prefer different reporting formats than those in Europe, and we adapt accordingly. This level of personalization helps boost efficiency and user satisfaction, making our services feel native to each market without compromising on quality or consistency.

We also offer scalable support that evolves with your global expansion. As you enter new territories, we adjust timelines, resources, and communication channels to align with local time zones and business practices. This proactive customization minimizes disruptions and maximizes collaboration, ensuring a smooth experience no matter where you operate.

Sustainability Practices in Hanger Bolt Production

In hanger bolt production, implementing sustainable practices often starts with sourcing materials responsibly. Manufacturers are increasingly opting for recycled steel or aluminum, which not only reduces the demand for virgin resources but also cuts down on energy-intensive extraction processes. For instance, using scrap metal can lower carbon emissions by up to 60% compared to traditional methods, making bolts more eco-friendly from the outset. This shift towards circular economy principles ensures that materials are reused whenever possible, minimizing waste and environmental impact.

Another key aspect is energy efficiency in manufacturing. By upgrading to modern machinery and adopting renewable energy sources like solar or wind power, factories can significantly decrease their carbon footprint. Some producers have even redesigned their production lines to optimize energy use, leading to faster, cleaner bolt creation without compromising quality. These changes not only save costs in the long run but also align with global sustainability goals, offering a competitive edge in markets where green credentials matter.

Beyond the factory floor, sustainable hanger bolt production extends to end-of-life considerations. Many companies now design bolts for easy disassembly and recycling, encouraging customers to return used products for reprocessing. This cradle-to-cradle approach reduces landfill waste and promotes a closed-loop system, where old bolts become raw materials for new ones. By focusing on durability and recyclability, the industry is moving towards a more resilient and environmentally conscious future.

Market Insights and Export Capabilities

Understanding market dynamics is crucial for businesses aiming to expand their reach globally. Our firm specializes in offering real-time analysis of emerging trends and consumer behaviors across various sectors, helping you identify untapped opportunities and potential risks. By leveraging advanced data analytics and industry expertise, we provide actionable insights that can inform your strategic decisions, whether you're entering a new market or optimizing existing operations.

In addition to market insights, our export capabilities are designed to streamline your international trade processes. We offer comprehensive support in logistics, compliance, and customs documentation, ensuring a smooth transition from production to delivery. Our network of global partners and tailored solutions enables businesses of all sizes to overcome common export challenges, such as regulatory hurdles and supply chain disruptions, fostering sustainable growth in competitive environments.

What sets us apart is our integrated approach that combines in-depth market research with hands-on export assistance, creating a seamless pathway to global success. By continuously adapting to economic shifts and technological advancements, we empower clients to not only respond to market changes but also to anticipate them, building resilience and competitive advantage in an ever-evolving landscape.

FAQ

Hanger bolts are threaded fasteners featuring a wood screw thread on one end and a machine screw thread on the other. They're commonly used to attach wood to metal components, such as in furniture legs, automotive parts, and industrial machinery.

Key manufacturing hubs include Zhejiang Province, particularly Wenzhou and Ningbo, and Guangdong Province. These areas have developed robust supply chains and skilled labor forces specializing in fasteners.

Many factories implement strict quality control processes, such as using high-grade steel or stainless steel materials, conducting tensile strength tests, and applying corrosion-resistant coatings like zinc plating or galvanizing.

Important considerations include the manufacturer's production capacity, compliance with international standards like ISO or ASTM, customization options, lead times, and after-sales support or warranty policies.

Yes, industries such as furniture manufacturing, automotive assembly, construction, and agricultural equipment production frequently source these components due to their cost-effectiveness and versatility.

Suppliers often offer customizations in thread sizes, lengths, materials (e.g., carbon steel, brass), finishes, and packaging. Some may even provide design assistance for specialized applications.

Advancements like automated threading machines, CNC precision tools, and digital inspection systems have enhanced efficiency, consistency, and reduced waste in manufacturing processes.

Conclusion

China's hanger bolt factories are led by prominent manufacturers known for their large-scale production and adherence to international standards, positioning them as key players globally. These leading producers combine advanced technologies with robust export capabilities, allowing them to efficiently serve markets worldwide. In terms of quality, key features like precision engineering and durable materials are prioritized, ensuring reliable fastening solutions. Innovation trends in the industry include automation and smart manufacturing processes, which enhance efficiency and customization options for global clients, tailored to specific needs. This adaptability helps factories maintain competitiveness and meet diverse demands.

Moreover, sustainability practices are increasingly integrated into production, focusing on eco-friendly materials and reduced waste, aligning with global environmental goals. Market insights reveal that Chinese manufacturers leverage strategic insights to navigate trends and expand their reach. Overall, these top factories excel by blending quality, innovation, and sustainability, making them a reliable choice for businesses seeking effective and sustainable hanger bolt solutions.

Contact Us

Contact Person: Nancy

Email: [email protected]

Tel/WhatsApp: +86-13365923720

Website: https://www.topfencesolar.com/