UL FM Gate Valve Manufacturer: Top Solutions for Safety-Critical Fluid Control

2025-12-22

In industries where safety-critical fluid control is non-negotiable, selecting the right UL FM Gate Valve manufacturer can make all the difference. At DRIFCO, we specialize in delivering top-notch solutions that not only meet rigorous standards but exceed expectations with innovative design and unwavering reliability. This blog will explore how DRIFCO's products stand out in the market, ensuring optimal performance and peace of mind in the most demanding environments. Dive in to discover insights on enhancing your fluid control systems and why partnering with a trusted leader like DRIFCO is a smart move for safety and efficiency.

Enhancing Industrial Safety with UL-FM Certified Gate Valve Solutions

In industries ranging from oil and gas to water treatment, the reliability of gate valves is paramount for maintaining operational safety and efficiency. UL-FM certification ensures these valves meet rigorous standards for fire resistance, flow control, and durability under extreme conditions. By incorporating certified solutions, facilities can significantly reduce the risk of leaks, pressure failures, and hazardous incidents, providing peace of mind in high-stakes environments.

Unlike standard valves, UL-FM certified gate valves undergo extensive testing, including simulations of long-term wear and emergency scenarios, guaranteeing consistent performance even after years of use. This proactive approach to safety not only helps prevent costly downtime and environmental damage but also supports compliance with stringent regulatory frameworks, making them a smart investment for forward-thinking companies aiming to enhance their safety protocols.

Navigating High-Risk Fluid Control Applications with Reliable Gate Valves

In industries ranging from oil and gas to water treatment, the reliability of gate valves is paramount for maintaining operational safety and efficiency. UL-FM certification ensures these valves meet rigorous standards for fire resistance, flow control, and durability under extreme conditions. By incorporating certified solutions, facilities can significantly reduce the risk of leaks, pressure failures, and hazardous incidents, providing peace of mind in high-stakes environments.

Unlike standard valves, UL-FM certified gate valves undergo extensive testing, including simulations of long-term wear and emergency scenarios, guaranteeing consistent performance even after years of use. This proactive approach to safety not only helps prevent costly downtime and environmental damage but also supports compliance with stringent regulatory frameworks, making them a smart investment for forward-thinking companies aiming to enhance their safety protocols.

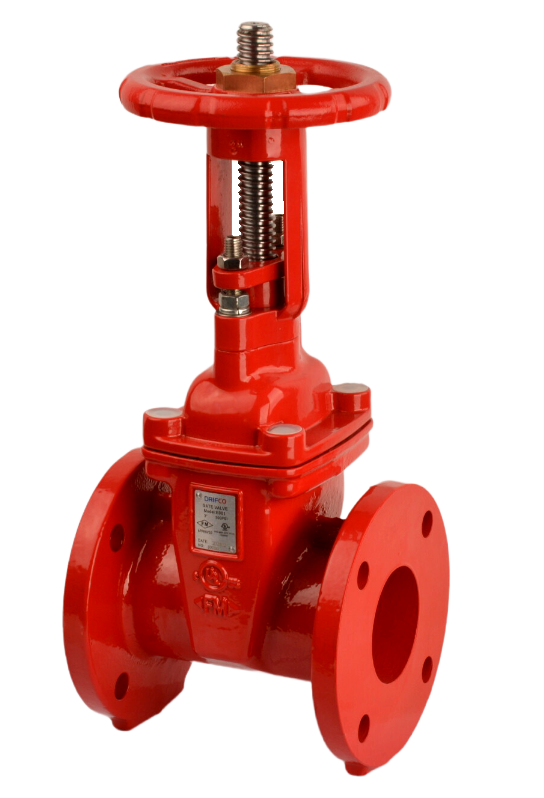

In environments where fluid control carries high stakes, such as oil refineries, chemical plants, or water treatment facilities, gate valves emerge as critical components due to their straightforward design and robust performance. Unlike other valve types that might rely on complex mechanisms, gate valves operate with a simple sliding gate that moves perpendicular to the flow, offering a clear, unobstructed passage when fully open. This minimalistic approach not only enhances durability but also reduces maintenance needs, making them a top choice for operators managing volatile substances. By ensuring a tight seal in the closed position, these valves help prevent leaks that could lead to environmental hazards or safety incidents, providing peace of mind in high-pressure scenarios.

What sets reliable gate valves apart in high-risk applications is their adaptability to extreme conditions, including corrosive materials, high temperatures, and abrasive slurries. Manufacturers often craft these valves from materials like stainless steel, duplex alloys, or specialized coatings that resist degradation over time. Additionally, features such as rising stems allow for easy visual confirmation of valve position, a small but crucial detail in fast-paced industrial settings where missteps can have severe consequences. By integrating with automated control systems, gate valves enable remote operation and monitoring, further reducing human error and enhancing overall system resilience against unexpected failures.

Ultimately, navigating high-risk fluid control isn't just about selecting any valve; it's about choosing gate valves that have been rigorously tested and proven in real-world scenarios. Industry standards and certifications play a key role here, ensuring that each valve meets stringent safety and performance criteria before deployment. By focusing on reliability through quality manufacturing and regular inspections, facilities can mitigate risks effectively, turning potential vulnerabilities into controlled, manageable processes. This proactive approach not only safeguards assets and personnel but also optimizes operational efficiency, making gate valves indispensable in the pursuit of safer, more sustainable industrial operations.

Innovative Manufacturing Techniques for Durable UL-FM Gate Valves

In industries ranging from oil and gas to water treatment, the reliability of gate valves is paramount for maintaining operational safety and efficiency. UL-FM certification ensures these valves meet rigorous standards for fire resistance, flow control, and durability under extreme conditions. By incorporating certified solutions, facilities can significantly reduce the risk of leaks, pressure failures, and hazardous incidents, providing peace of mind in high-stakes environments.

Unlike standard valves, UL-FM certified gate valves undergo extensive testing, including simulations of long-term wear and emergency scenarios, guaranteeing consistent performance even after years of use. This proactive approach to safety not only helps prevent costly downtime and environmental damage but also supports compliance with stringent regulatory frameworks, making them a smart investment for forward-thinking companies aiming to enhance their safety protocols.

In environments where fluid control carries high stakes, such as oil refineries, chemical plants, or water treatment facilities, gate valves emerge as critical components due to their straightforward design and robust performance. Unlike other valve types that might rely on complex mechanisms, gate valves operate with a simple sliding gate that moves perpendicular to the flow, offering a clear, unobstructed passage when fully open. This minimalistic approach not only enhances durability but also reduces maintenance needs, making them a top choice for operators managing volatile substances. By ensuring a tight seal in the closed position, these valves help prevent leaks that could lead to environmental hazards or safety incidents, providing peace of mind in high-pressure scenarios.

What sets reliable gate valves apart in high-risk applications is their adaptability to extreme conditions, including corrosive materials, high temperatures, and abrasive slurries. Manufacturers often craft these valves from materials like stainless steel, duplex alloys, or specialized coatings that resist degradation over time. Additionally, features such as rising stems allow for easy visual confirmation of valve position, a small but crucial detail in fast-paced industrial settings where missteps can have severe consequences. By integrating with automated control systems, gate valves enable remote operation and monitoring, further reducing human error and enhancing overall system resilience against unexpected failures.

Ultimately, navigating high-risk fluid control isn't just about selecting any valve; it's about choosing gate valves that have been rigorously tested and proven in real-world scenarios. Industry standards and certifications play a key role here, ensuring that each valve meets stringent safety and performance criteria before deployment. By focusing on reliability through quality manufacturing and regular inspections, facilities can mitigate risks effectively, turning potential vulnerabilities into controlled, manageable processes. This proactive approach not only safeguards assets and personnel but also optimizes operational efficiency, making gate valves indispensable in the pursuit of safer, more sustainable industrial operations.

In the realm of industrial fluid control, UL-FM gate valves stand out for their reliability in demanding applications such as fire protection systems. To elevate their durability, cutting-edge manufacturing techniques are now being integrated into production processes. These include additive manufacturing (3D printing) for complex, lightweight components that reduce stress points, and precision CNC machining for enhanced sealing surfaces and smoother operation. Such innovations not only extend the valve's lifespan but also ensure compliance with UL and FM standards, providing cost-effective solutions for critical infrastructure.

Beyond traditional methods, the adoption of advanced materials science plays a pivotal role in crafting durable UL-FM gate valves. By employing high-strength alloys and corrosion-resistant coatings, manufacturers can mitigate wear and tear from harsh environments. This is complemented by automated assembly lines equipped with real-time quality control sensors, which detect micro-defects before installation, minimizing failure risks. As a result, these valves deliver superior performance with minimal maintenance, setting a new benchmark for safety and efficiency in fluid management systems.

Emerging trends like smart manufacturing and IoT integration further revolutionize the production of UL-FM gate valves. Embedded with sensors, these valves can monitor pressure and temperature in real-time, enabling predictive maintenance and reducing downtime. This proactive approach, combined with eco-friendly processes such as water-based coatings, ensures sustainability alongside durability. By embracing these innovative techniques, the industry not only meets regulatory demands but also drives forward a future of resilient, intelligent fluid control solutions.

Optimizing Performance and Compliance in Critical Fluid Management Systems

In industries ranging from oil and gas to water treatment, the reliability of gate valves is paramount for maintaining operational safety and efficiency. UL-FM certification ensures these valves meet rigorous standards for fire resistance, flow control, and durability under extreme conditions. By incorporating certified solutions, facilities can significantly reduce the risk of leaks, pressure failures, and hazardous incidents, providing peace of mind in high-stakes environments.

Unlike standard valves, UL-FM certified gate valves undergo extensive testing, including simulations of long-term wear and emergency scenarios, guaranteeing consistent performance even after years of use. This proactive approach to safety not only helps prevent costly downtime and environmental damage but also supports compliance with stringent regulatory frameworks, making them a smart investment for forward-thinking companies aiming to enhance their safety protocols.

In environments where fluid control carries high stakes, such as oil refineries, chemical plants, or water treatment facilities, gate valves emerge as critical components due to their straightforward design and robust performance. Unlike other valve types that might rely on complex mechanisms, gate valves operate with a simple sliding gate that moves perpendicular to the flow, offering a clear, unobstructed passage when fully open. This minimalistic approach not only enhances durability but also reduces maintenance needs, making them a top choice for operators managing volatile substances. By ensuring a tight seal in the closed position, these valves help prevent leaks that could lead to environmental hazards or safety incidents, providing peace of mind in high-pressure scenarios.

What sets reliable gate valves apart in high-risk applications is their adaptability to extreme conditions, including corrosive materials, high temperatures, and abrasive slurries. Manufacturers often craft these valves from materials like stainless steel, duplex alloys, or specialized coatings that resist degradation over time. Additionally, features such as rising stems allow for easy visual confirmation of valve position, a small but crucial detail in fast-paced industrial settings where missteps can have severe consequences. By integrating with automated control systems, gate valves enable remote operation and monitoring, further reducing human error and enhancing overall system resilience against unexpected failures.

Ultimately, navigating high-risk fluid control isn't just about selecting any valve; it's about choosing gate valves that have been rigorously tested and proven in real-world scenarios. Industry standards and certifications play a key role here, ensuring that each valve meets stringent safety and performance criteria before deployment. By focusing on reliability through quality manufacturing and regular inspections, facilities can mitigate risks effectively, turning potential vulnerabilities into controlled, manageable processes. This proactive approach not only safeguards assets and personnel but also optimizes operational efficiency, making gate valves indispensable in the pursuit of safer, more sustainable industrial operations.

In the realm of industrial fluid control, UL-FM gate valves stand out for their reliability in demanding applications such as fire protection systems. To elevate their durability, cutting-edge manufacturing techniques are now being integrated into production processes. These include additive manufacturing (3D printing) for complex, lightweight components that reduce stress points, and precision CNC machining for enhanced sealing surfaces and smoother operation. Such innovations not only extend the valve's lifespan but also ensure compliance with UL and FM standards, providing cost-effective solutions for critical infrastructure.

Beyond traditional methods, the adoption of advanced materials science plays a pivotal role in crafting durable UL-FM gate valves. By employing high-strength alloys and corrosion-resistant coatings, manufacturers can mitigate wear and tear from harsh environments. This is complemented by automated assembly lines equipped with real-time quality control sensors, which detect micro-defects before installation, minimizing failure risks. As a result, these valves deliver superior performance with minimal maintenance, setting a new benchmark for safety and efficiency in fluid management systems.

Emerging trends like smart manufacturing and IoT integration further revolutionize the production of UL-FM gate valves. Embedded with sensors, these valves can monitor pressure and temperature in real-time, enabling predictive maintenance and reducing downtime. This proactive approach, combined with eco-friendly processes such as water-based coatings, ensures sustainability alongside durability. By embracing these innovative techniques, the industry not only meets regulatory demands but also drives forward a future of resilient, intelligent fluid control solutions.

In today's high-stakes industrial environments, critical fluid management systems serve as the lifeblood of operations, whether in pharmaceuticals, petrochemicals, or semiconductor manufacturing. Optimizing these systems isn't just about boosting efficiency; it's a delicate balance between enhancing performance and ensuring stringent compliance with regulatory standards. By integrating advanced monitoring technologies, such as real-time sensors and predictive analytics, companies can proactively manage fluid quality, flow rates, and pressure levels, reducing downtime and minimizing risks of contamination or system failures. This holistic approach not only drives operational excellence but also aligns with global guidelines like FDA or ISO certifications, making compliance a seamless part of the performance improvement journey.

To stand out in a crowded field, it's crucial to adopt customized strategies that go beyond generic solutions. For instance, leveraging machine learning algorithms to analyze historical data can uncover hidden patterns and predict maintenance needs before issues escalate, thereby preventing costly shutdowns. Additionally, implementing modular designs allows for flexible scalability, adapting to changing production demands without compromising compliance. Emphasizing a sustainability angle, such as reducing water usage or recycling fluids, can further differentiate a system, appealing to eco-conscious stakeholders while meeting environmental regulations. This nuanced focus on innovation and adaptability ensures that fluid management systems not only meet but exceed industry benchmarks.

Ultimately, the key to success lies in fostering a culture of continuous improvement and cross-functional collaboration. Engaging teams from engineering, quality control, and regulatory affairs ensures that performance enhancements are vetted for compliance at every stage. Regular audits and transparent reporting mechanisms build trust with regulators and clients alike, turning compliance from a burden into a competitive advantage. By blending cutting-edge technology with robust governance frameworks, organizations can achieve a harmonious synergy where optimized performance and unwavering compliance reinforce each other, driving long-term resilience and growth in critical sectors.

Sizing and Selection Guide for UL-FM Gate Valves Across Different Industries

In industries ranging from oil and gas to water treatment, the reliability of gate valves is paramount for maintaining operational safety and efficiency. UL-FM certification ensures these valves meet rigorous standards for fire resistance, flow control, and durability under extreme conditions. By incorporating certified solutions, facilities can significantly reduce the risk of leaks, pressure failures, and hazardous incidents, providing peace of mind in high-stakes environments.

Unlike standard valves, UL-FM certified gate valves undergo extensive testing, including simulations of long-term wear and emergency scenarios, guaranteeing consistent performance even after years of use. This proactive approach to safety not only helps prevent costly downtime and environmental damage but also supports compliance with stringent regulatory frameworks, making them a smart investment for forward-thinking companies aiming to enhance their safety protocols.

In environments where fluid control carries high stakes, such as oil refineries, chemical plants, or water treatment facilities, gate valves emerge as critical components due to their straightforward design and robust performance. Unlike other valve types that might rely on complex mechanisms, gate valves operate with a simple sliding gate that moves perpendicular to the flow, offering a clear, unobstructed passage when fully open. This minimalistic approach not only enhances durability but also reduces maintenance needs, making them a top choice for operators managing volatile substances. By ensuring a tight seal in the closed position, these valves help prevent leaks that could lead to environmental hazards or safety incidents, providing peace of mind in high-pressure scenarios.

What sets reliable gate valves apart in high-risk applications is their adaptability to extreme conditions, including corrosive materials, high temperatures, and abrasive slurries. Manufacturers often craft these valves from materials like stainless steel, duplex alloys, or specialized coatings that resist degradation over time. Additionally, features such as rising stems allow for easy visual confirmation of valve position, a small but crucial detail in fast-paced industrial settings where missteps can have severe consequences. By integrating with automated control systems, gate valves enable remote operation and monitoring, further reducing human error and enhancing overall system resilience against unexpected failures.

Ultimately, navigating high-risk fluid control isn't just about selecting any valve; it's about choosing gate valves that have been rigorously tested and proven in real-world scenarios. Industry standards and certifications play a key role here, ensuring that each valve meets stringent safety and performance criteria before deployment. By focusing on reliability through quality manufacturing and regular inspections, facilities can mitigate risks effectively, turning potential vulnerabilities into controlled, manageable processes. This proactive approach not only safeguards assets and personnel but also optimizes operational efficiency, making gate valves indispensable in the pursuit of safer, more sustainable industrial operations.

In the realm of industrial fluid control, UL-FM gate valves stand out for their reliability in demanding applications such as fire protection systems. To elevate their durability, cutting-edge manufacturing techniques are now being integrated into production processes. These include additive manufacturing (3D printing) for complex, lightweight components that reduce stress points, and precision CNC machining for enhanced sealing surfaces and smoother operation. Such innovations not only extend the valve's lifespan but also ensure compliance with UL and FM standards, providing cost-effective solutions for critical infrastructure.

Beyond traditional methods, the adoption of advanced materials science plays a pivotal role in crafting durable UL-FM gate valves. By employing high-strength alloys and corrosion-resistant coatings, manufacturers can mitigate wear and tear from harsh environments. This is complemented by automated assembly lines equipped with real-time quality control sensors, which detect micro-defects before installation, minimizing failure risks. As a result, these valves deliver superior performance with minimal maintenance, setting a new benchmark for safety and efficiency in fluid management systems.

Emerging trends like smart manufacturing and IoT integration further revolutionize the production of UL-FM gate valves. Embedded with sensors, these valves can monitor pressure and temperature in real-time, enabling predictive maintenance and reducing downtime. This proactive approach, combined with eco-friendly processes such as water-based coatings, ensures sustainability alongside durability. By embracing these innovative techniques, the industry not only meets regulatory demands but also drives forward a future of resilient, intelligent fluid control solutions.

In today's high-stakes industrial environments, critical fluid management systems serve as the lifeblood of operations, whether in pharmaceuticals, petrochemicals, or semiconductor manufacturing. Optimizing these systems isn't just about boosting efficiency; it's a delicate balance between enhancing performance and ensuring stringent compliance with regulatory standards. By integrating advanced monitoring technologies, such as real-time sensors and predictive analytics, companies can proactively manage fluid quality, flow rates, and pressure levels, reducing downtime and minimizing risks of contamination or system failures. This holistic approach not only drives operational excellence but also aligns with global guidelines like FDA or ISO certifications, making compliance a seamless part of the performance improvement journey.

To stand out in a crowded field, it's crucial to adopt customized strategies that go beyond generic solutions. For instance, leveraging machine learning algorithms to analyze historical data can uncover hidden patterns and predict maintenance needs before issues escalate, thereby preventing costly shutdowns. Additionally, implementing modular designs allows for flexible scalability, adapting to changing production demands without compromising compliance. Emphasizing a sustainability angle, such as reducing water usage or recycling fluids, can further differentiate a system, appealing to eco-conscious stakeholders while meeting environmental regulations. This nuanced focus on innovation and adaptability ensures that fluid management systems not only meet but exceed industry benchmarks.

Ultimately, the key to success lies in fostering a culture of continuous improvement and cross-functional collaboration. Engaging teams from engineering, quality control, and regulatory affairs ensures that performance enhancements are vetted for compliance at every stage. Regular audits and transparent reporting mechanisms build trust with regulators and clients alike, turning compliance from a burden into a competitive advantage. By blending cutting-edge technology with robust governance frameworks, organizations can achieve a harmonious synergy where optimized performance and unwavering compliance reinforce each other, driving long-term resilience and growth in critical sectors.

Understanding the nuances of sizing and selecting UL-FM gate valves is crucial for ensuring optimal performance and compliance across diverse industrial applications. These valves are commonly utilized in fire protection systems where they must meet stringent standards from Underwriters Laboratories (UL) and Factory Mutual (FM) for reliability and safety. When choosing a gate valve, factors such as pipe diameter, pressure requirements, and material compatibility play a key role. For instance, in chemical processing plants, corrosion-resistant materials like stainless steel or bronze are often preferred to handle aggressive fluids, while in water distribution networks, ductile iron might suffice. Proper sizing involves calculating flow rates and pressure drops to avoid issues like cavitation or inadequate flow, which can compromise system efficiency.

Different industries impose unique demands on UL-FM gate valves, necessitating tailored selection strategies. In the oil and gas sector, valves must withstand high pressures and extreme temperatures, often requiring robust designs with enhanced sealing mechanisms to prevent leaks in hazardous environments. Meanwhile, in commercial buildings or data centers, emphasis is placed on ease of installation and maintenance, with compact designs and lever-operated handles being popular choices. It's essential to consult manufacturer specifications and industry guidelines, as UL-FM certifications ensure that valves have undergone rigorous testing for fire resistance and operational durability. By aligning valve characteristics with specific industrial needs, users can enhance system longevity and safety while meeting regulatory standards.

To stand out in the market, selecting UL-FM gate valves should go beyond basic compliance and consider environmental and operational versatility. Innovations like bi-directional flow capabilities or anti-seize stem designs can offer advantages in applications prone to sediment buildup or frequent cycling. Regular maintenance, including lubrication and inspection, is vital to prolong valve life, especially in industries like maritime or wastewater treatment where exposure to harsh conditions is common. Ultimately, a well-informed selection process not only prevents costly downtime but also contributes to sustainable operations by optimizing resource use and minimizing environmental risks.

Future Trends in Safety-Critical Fluid Control: Integrating Smart Technologies

In industries ranging from oil and gas to water treatment, the reliability of gate valves is paramount for maintaining operational safety and efficiency. UL-FM certification ensures these valves meet rigorous standards for fire resistance, flow control, and durability under extreme conditions. By incorporating certified solutions, facilities can significantly reduce the risk of leaks, pressure failures, and hazardous incidents, providing peace of mind in high-stakes environments.

Unlike standard valves, UL-FM certified gate valves undergo extensive testing, including simulations of long-term wear and emergency scenarios, guaranteeing consistent performance even after years of use. This proactive approach to safety not only helps prevent costly downtime and environmental damage but also supports compliance with stringent regulatory frameworks, making them a smart investment for forward-thinking companies aiming to enhance their safety protocols.

In environments where fluid control carries high stakes, such as oil refineries, chemical plants, or water treatment facilities, gate valves emerge as critical components due to their straightforward design and robust performance. Unlike other valve types that might rely on complex mechanisms, gate valves operate with a simple sliding gate that moves perpendicular to the flow, offering a clear, unobstructed passage when fully open. This minimalistic approach not only enhances durability but also reduces maintenance needs, making them a top choice for operators managing volatile substances. By ensuring a tight seal in the closed position, these valves help prevent leaks that could lead to environmental hazards or safety incidents, providing peace of mind in high-pressure scenarios.

What sets reliable gate valves apart in high-risk applications is their adaptability to extreme conditions, including corrosive materials, high temperatures, and abrasive slurries. Manufacturers often craft these valves from materials like stainless steel, duplex alloys, or specialized coatings that resist degradation over time. Additionally, features such as rising stems allow for easy visual confirmation of valve position, a small but crucial detail in fast-paced industrial settings where missteps can have severe consequences. By integrating with automated control systems, gate valves enable remote operation and monitoring, further reducing human error and enhancing overall system resilience against unexpected failures.

Ultimately, navigating high-risk fluid control isn't just about selecting any valve; it's about choosing gate valves that have been rigorously tested and proven in real-world scenarios. Industry standards and certifications play a key role here, ensuring that each valve meets stringent safety and performance criteria before deployment. By focusing on reliability through quality manufacturing and regular inspections, facilities can mitigate risks effectively, turning potential vulnerabilities into controlled, manageable processes. This proactive approach not only safeguards assets and personnel but also optimizes operational efficiency, making gate valves indispensable in the pursuit of safer, more sustainable industrial operations.

In the realm of industrial fluid control, UL-FM gate valves stand out for their reliability in demanding applications such as fire protection systems. To elevate their durability, cutting-edge manufacturing techniques are now being integrated into production processes. These include additive manufacturing (3D printing) for complex, lightweight components that reduce stress points, and precision CNC machining for enhanced sealing surfaces and smoother operation. Such innovations not only extend the valve's lifespan but also ensure compliance with UL and FM standards, providing cost-effective solutions for critical infrastructure.

Beyond traditional methods, the adoption of advanced materials science plays a pivotal role in crafting durable UL-FM gate valves. By employing high-strength alloys and corrosion-resistant coatings, manufacturers can mitigate wear and tear from harsh environments. This is complemented by automated assembly lines equipped with real-time quality control sensors, which detect micro-defects before installation, minimizing failure risks. As a result, these valves deliver superior performance with minimal maintenance, setting a new benchmark for safety and efficiency in fluid management systems.

Emerging trends like smart manufacturing and IoT integration further revolutionize the production of UL-FM gate valves. Embedded with sensors, these valves can monitor pressure and temperature in real-time, enabling predictive maintenance and reducing downtime. This proactive approach, combined with eco-friendly processes such as water-based coatings, ensures sustainability alongside durability. By embracing these innovative techniques, the industry not only meets regulatory demands but also drives forward a future of resilient, intelligent fluid control solutions.

In today's high-stakes industrial environments, critical fluid management systems serve as the lifeblood of operations, whether in pharmaceuticals, petrochemicals, or semiconductor manufacturing. Optimizing these systems isn't just about boosting efficiency; it's a delicate balance between enhancing performance and ensuring stringent compliance with regulatory standards. By integrating advanced monitoring technologies, such as real-time sensors and predictive analytics, companies can proactively manage fluid quality, flow rates, and pressure levels, reducing downtime and minimizing risks of contamination or system failures. This holistic approach not only drives operational excellence but also aligns with global guidelines like FDA or ISO certifications, making compliance a seamless part of the performance improvement journey.

To stand out in a crowded field, it's crucial to adopt customized strategies that go beyond generic solutions. For instance, leveraging machine learning algorithms to analyze historical data can uncover hidden patterns and predict maintenance needs before issues escalate, thereby preventing costly shutdowns. Additionally, implementing modular designs allows for flexible scalability, adapting to changing production demands without compromising compliance. Emphasizing a sustainability angle, such as reducing water usage or recycling fluids, can further differentiate a system, appealing to eco-conscious stakeholders while meeting environmental regulations. This nuanced focus on innovation and adaptability ensures that fluid management systems not only meet but exceed industry benchmarks.

Ultimately, the key to success lies in fostering a culture of continuous improvement and cross-functional collaboration. Engaging teams from engineering, quality control, and regulatory affairs ensures that performance enhancements are vetted for compliance at every stage. Regular audits and transparent reporting mechanisms build trust with regulators and clients alike, turning compliance from a burden into a competitive advantage. By blending cutting-edge technology with robust governance frameworks, organizations can achieve a harmonious synergy where optimized performance and unwavering compliance reinforce each other, driving long-term resilience and growth in critical sectors.

Understanding the nuances of sizing and selecting UL-FM gate valves is crucial for ensuring optimal performance and compliance across diverse industrial applications. These valves are commonly utilized in fire protection systems where they must meet stringent standards from Underwriters Laboratories (UL) and Factory Mutual (FM) for reliability and safety. When choosing a gate valve, factors such as pipe diameter, pressure requirements, and material compatibility play a key role. For instance, in chemical processing plants, corrosion-resistant materials like stainless steel or bronze are often preferred to handle aggressive fluids, while in water distribution networks, ductile iron might suffice. Proper sizing involves calculating flow rates and pressure drops to avoid issues like cavitation or inadequate flow, which can compromise system efficiency.

Different industries impose unique demands on UL-FM gate valves, necessitating tailored selection strategies. In the oil and gas sector, valves must withstand high pressures and extreme temperatures, often requiring robust designs with enhanced sealing mechanisms to prevent leaks in hazardous environments. Meanwhile, in commercial buildings or data centers, emphasis is placed on ease of installation and maintenance, with compact designs and lever-operated handles being popular choices. It's essential to consult manufacturer specifications and industry guidelines, as UL-FM certifications ensure that valves have undergone rigorous testing for fire resistance and operational durability. By aligning valve characteristics with specific industrial needs, users can enhance system longevity and safety while meeting regulatory standards.

To stand out in the market, selecting UL-FM gate valves should go beyond basic compliance and consider environmental and operational versatility. Innovations like bi-directional flow capabilities or anti-seize stem designs can offer advantages in applications prone to sediment buildup or frequent cycling. Regular maintenance, including lubrication and inspection, is vital to prolong valve life, especially in industries like maritime or wastewater treatment where exposure to harsh conditions is common. Ultimately, a well-informed selection process not only prevents costly downtime but also contributes to sustainable operations by optimizing resource use and minimizing environmental risks.

The integration of smart technologies into safety-critical fluid control systems is transforming how industries manage hazardous or essential fluids, from chemicals in manufacturing to fuel in aerospace. By embedding sensors, IoT connectivity, and AI-driven analytics, these systems now offer real-time monitoring and predictive maintenance, drastically reducing the risk of leaks, contamination, or failures that could lead to catastrophic events. For instance, in oil and gas pipelines, smart valves can detect pressure anomalies and automatically adjust flow, preventing spills before they occur, while in pharmaceutical production, automated controls ensure precise fluid handling to maintain product purity and compliance with stringent regulations.

A key trend is the shift from reactive to proactive safety management through digital twins and machine learning. By creating virtual replicas of fluid control systems, engineers can simulate scenarios and optimize performance under various conditions, identifying potential vulnerabilities without physical testing. This approach not only enhances reliability but also cuts downtime and costs. In aviation, for example, smart hydraulic systems use data from past flights to predict component wear, scheduling maintenance only when needed, rather than relying on fixed intervals—saving time and improving safety by addressing issues before they escalate.

Emerging innovations like edge computing and blockchain are further revolutionizing this field, enabling decentralized control and enhanced traceability. Edge devices process data locally at the source, allowing for faster response times in critical situations, such as emergency shutdowns in nuclear plants. Meanwhile, blockchain technology provides immutable records of fluid transactions and maintenance logs, ensuring transparency and accountability in industries prone to regulatory scrutiny. These advancements not only bolster safety but also foster trust among stakeholders, paving the way for more resilient and adaptive fluid control infrastructures globally.

FAQ

Safety in fluid control systems hinges on robust design, reliable components, and adherence to strict standards like UL and FM certifications, which ensure valves perform under extreme conditions.

UL FM gate valves boost security by providing fire-safe shutoff, leak-proof sealing, and resistance to corrosion, critical for preventing accidents in chemical, oil, and gas industries.

Prioritizing UL FM certifications ensures compliance with safety regulations, builds customer trust, and reduces liability risks, as these valves are tested for fire and mechanical performance.

Top solutions stand out through advanced materials like stainless steel, innovative sealing technologies, and comprehensive testing protocols, offering longer service life and lower maintenance costs.

Yes, leading manufacturers offer customization in size, material, and pressure ratings to meet unique needs in power generation, water treatment, or hazardous environments.

Challenges include wear from high pressure or corrosion; addressing them involves regular inspections, using compatible fluids, and opting for valves with self-lubricating features.

They contribute by preventing fluid leaks and spills, supporting containment in eco-sensitive areas, and aligning with green initiatives through durable, recyclable materials.

Conclusion

Industrial operations dealing with hazardous or high-pressure fluids require exceptionally reliable equipment, and gate valves certified by UL-FM stand at the forefront of ensuring safety in these settings. Such valves undergo rigorous testing to meet stringent standards for fire safety, performance, and durability, making them indispensable in applications where failure is not an option. By incorporating innovative manufacturing techniques, manufacturers produce valves that withstand extreme conditions, from corrosive chemicals to high-temperature environments. This durability is crucial for navigating high-risk fluid control scenarios, where even minor leaks can lead to catastrophic consequences. The focus on enhanced safety through certification not only protects assets but also safeguards personnel, aligning with industry demands for uncompromising reliability in fluid management systems.

Beyond basic compliance, selecting the right UL-FM gate valve involves careful sizing and consideration of specific industry needs, such as those in oil and gas, chemical processing, or water treatment. A thorough selection guide helps operators optimize performance, ensuring valves integrate seamlessly into critical systems without bottlenecks or inefficiencies. Looking ahead, the future of safety-critical fluid control is evolving with smart technologies, including IoT-enabled sensors and automated monitoring, which promise to revolutionize maintenance and real-time risk assessment. By embracing these trends, manufacturers can offer top solutions that not only meet current standards but also anticipate emerging challenges, positioning UL-FM gate valves as versatile tools for a safer, more efficient industrial landscape.

Contact Us

Contact Person: George

Email: [email protected]

Tel/WhatsApp: 13863633883

Website: https://www.es-fire.com