Benefits and Features of Pre-Folder Automatic Folder Gluer

2024-07-03

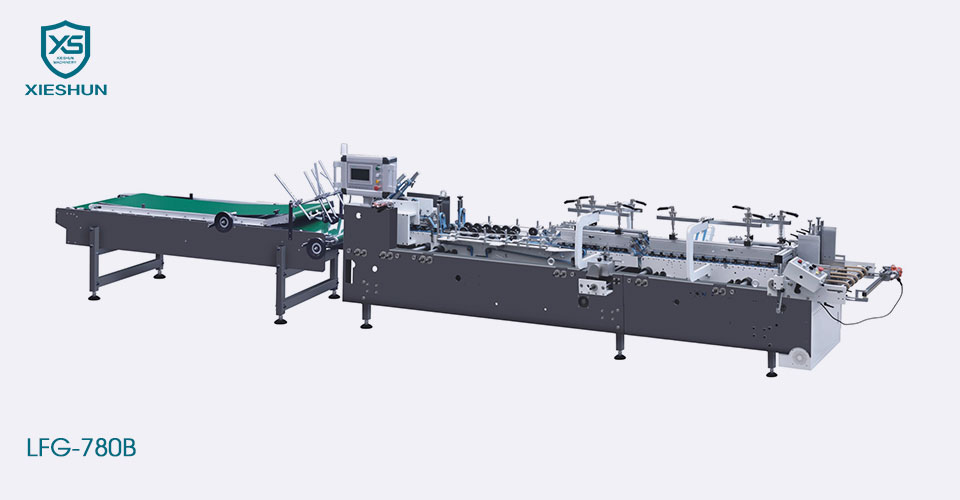

A pre-folder automatic folder gluer is a specialized machine used in the packaging industry to automate the folding and gluing of cardboard or corrugated paperboard into various types of boxes, cartons, or packaging containers. Here are the benefits and features of pre-folder automatic folder gluers:

Benefits:

1. Increased Productivity: Automating the folding and gluing process significantly increases production speed compared to manual methods. This enhances overall productivity and throughput in packaging operations.

2. Consistency and Accuracy: Automatic folder gluers ensure consistent folding and precise gluing of packaging materials, reducing errors and variability in box dimensions and quality.

3. Versatility: They can handle a wide range of box styles and sizes, from simple straight-line boxes to complex designs such as crash-lock bottom boxes or 4/6-corner boxes, making them versatile for various packaging needs.

4. Labor Savings: By automating repetitive tasks, pre-folder automatic folder gluers reduce the need for manual labor in folding and gluing operations, reallocating human resources to more skilled tasks.

5. Quality Control: These machines often include features such as optical sensors, electronic counters, and computerized controls that monitor and ensure consistent quality throughout the production run.

6. Quick Setup and Changeover: Modern pre-folder automatic folder gluers are designed for quick setup and changeover between different box sizes and styles. This flexibility reduces downtime between production runs.

7. Reduced Waste: Precise folding and gluing minimize material waste, optimizing material usage and reducing costs associated with raw materials.

8. Enhanced Safety: Automated folder gluers incorporate safety features such as guards, emergency stops, and safety interlocks to protect operators from potential hazards during operation.

Features:

1. Feeding System: Automatic feeder mechanisms ensure smooth and consistent feeding of sheets or blanks into the machine for processing.

2. Folding Section: Multiple folding stations with adjustable folding plates or belts accommodate different folding configurations and box styles.

3. Gluing System: Advanced gluing systems apply adhesive accurately and efficiently to ensure strong and secure bonding of box seams and flaps.

4. Compression and Stacking: Integrated compression sections and stacking mechanisms stack finished boxes neatly and uniformly for further processing or packaging.

5. Touchscreen Controls: User-friendly touchscreen interfaces allow operators to monitor and control machine settings, production parameters, and diagnostics easily.

6. Modular Design: Modular components and accessories can be added or adjusted to customize the machine according to specific production requirements or future upgrades.

7. Remote Monitoring: Some models may offer remote monitoring capabilities, allowing operators to monitor machine performance and diagnostics from a central control system.

8. Energy Efficiency: Energy-efficient motors and components help reduce operational costs and environmental impact during long production runs.

Pre-folder automatic folder gluers streamline the packaging process, offering efficiency, consistency, and versatility for manufacturers across various industries involved in cardboard and corrugated packaging production.