Components of Lightweight Cement Wall Panel Production Line

2024-06-15

A lightweight cement wall panel production line refers to a manufacturing setup designed to produce prefabricated panels made from lightweight cement-based materials. These panels offer advantages such as reduced weight, faster installation times, and improved thermal and acoustic insulation properties compared to traditional concrete or brick walls. Here's an overview of what a lightweight cement wall panel production line entails, its components, benefits, applications, and considerations:

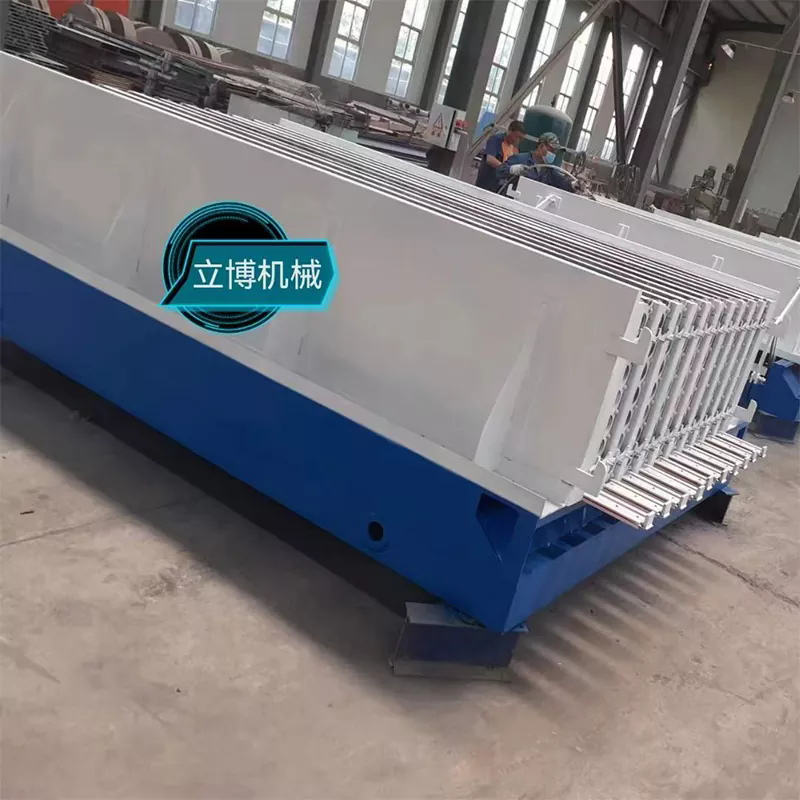

Components of Lightweight Cement Wall Panel Production Line

1. Raw Material Handling:

- Cement: Ordinary Portland cement or special lightweight cement formulations.

- Aggregates: Lightweight aggregates such as expanded polystyrene (EPS), perlite, vermiculite, or lightweight sand.

- Reinforcement: Optionally, fiberglass mesh, steel mesh, or other reinforcing materials.

- Additives: Chemical additives for improving properties like workability, strength, and curing characteristics.

2. Mixing and Batching System:

- Automated or semi-automated systems for accurate batching and mixing of raw materials.

- Mixers capable of blending cement, aggregates, water, and additives to achieve homogeneous mixtures.

3. Forming and Molding:

- Molds or forms where the cementitious mixture is poured or pressed to shape the panels.

- Vibrating tables or compacting systems to ensure proper compaction and removal of air bubbles.

4. Curing and Drying:

- Curing chambers or systems where panels undergo controlled curing processes to achieve desired strength and durability.

- Drying zones or ovens for accelerating drying of panels after curing.

5. Cutting and Sizing:

- Equipment for cutting panels to required dimensions and shapes.

- Edge trimming and profiling machines to refine panel edges for smooth assembly.

6. Surface Finishing and Coating:

- Surface treatment systems for applying coatings, textures, or finishes to panels as per design specifications.

- Painting or laminating equipment for adding decorative or protective layers.

7. Quality Control and Testing:

- Inspection stations for quality control checks on panel dimensions, surface finish, strength, and other properties.

- Testing equipment for conducting physical and mechanical tests to ensure panels meet industry standards.

Benefits of Lightweight Cement Wall Panels

1. Weight Reduction:

- Significantly lighter than traditional concrete or brick walls, easing transportation, handling, and installation.

2. Insulation Properties:

- Enhanced thermal and acoustic insulation capabilities, contributing to energy efficiency and comfort in buildings.

3. Speed of Installation:

- Prefabricated panels allow for rapid assembly and reduced construction time at the project site.

4. Design Flexibility:

- Panels can be customized in terms of size, shape, texture, and finish to meet architectural and aesthetic requirements.

5. Structural Strength:

- High strength-to-weight ratio, providing structural integrity and durability comparable to conventional building materials.

6. Environmental Benefits:

- Lower carbon footprint due to reduced energy consumption during production and transportation, as well as potential for recycling or reuse.

Applications of Lightweight Cement Wall Panels

1. Residential Construction:

- Used for interior and exterior walls in residential buildings, apartments, and modular homes.

2. Commercial and Industrial Buildings:

- Suitable for offices, retail spaces, warehouses, and industrial facilities requiring quick construction and efficient space utilization.

3. Institutional Buildings:

- Applications in schools, hospitals, hotels, and other institutional structures where rapid construction and superior performance are essential.

4. Infrastructure Projects:

- Utilized in infrastructure projects such as bridges, tunnels, and noise barriers where lightweight, durable panels are advantageous.

Considerations

1. Technical Expertise:

- Requires skilled operators and technicians familiar with the production process, quality control measures, and equipment maintenance.

2. Material Sourcing and Logistics:

- Ensure consistent supply of raw materials and efficient logistics to minimize production delays.

3. Regulatory Compliance:

- Adherence to local building codes, standards, and regulations governing the use of lightweight cement panels in construction.

4. Cost Considerations:

- Initial investment in production line equipment and operational costs should be balanced against long-term savings and benefits.

Future Trends

The future of lightweight cement wall panels production is likely to focus on:

- Advanced Materials: Development of new lightweight cement formulations and composite materials for enhanced performance.

- Automation and Robotics: Increased use of automation and robotics to improve production efficiency and reduce labor costs.

- Sustainability: Integration of sustainable practices such as recycling of materials and energy-efficient production methods.

In conclusion, a lightweight cement wall panel production line represents an innovative approach to modern construction methods, offering efficiency, versatility, and sustainability benefits. Understanding the production process, applications, and considerations is crucial for leveraging this technology in diverse building projects.