Detailed description of Automatic Brick Free Machine

2024-06-29

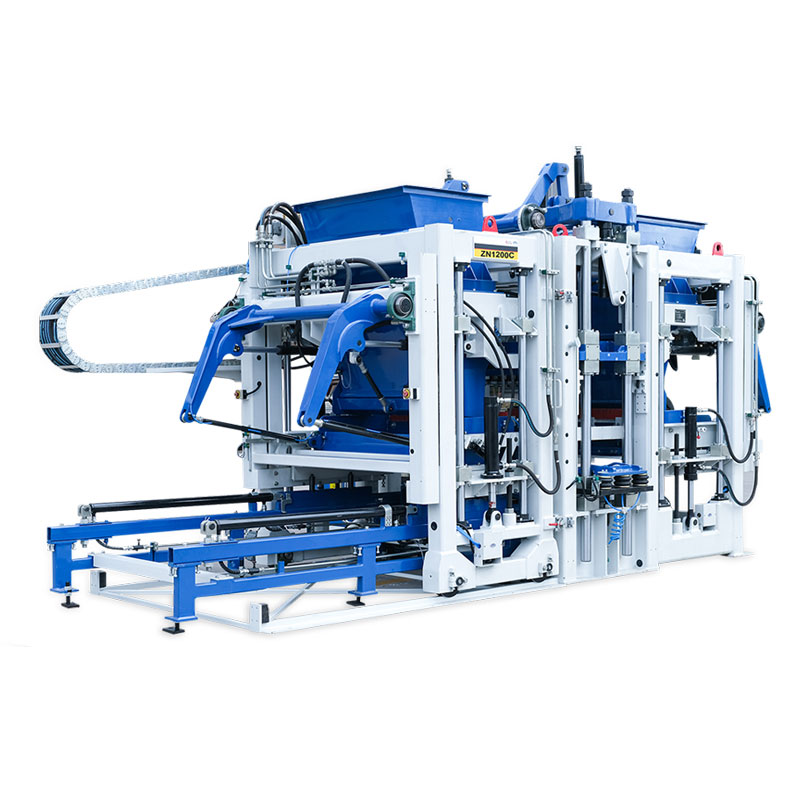

An Automatic Brick Free Machine typically refers to a specialized piece of equipment used in the construction industry for the production of bricks or blocks without the need for traditional molds or forms. Here’s a detailed description of what typically characterizes an Automatic Brick Free Machine:

1. Operational Principle:

- Modular System: The machine operates on a modular system that allows for the production of bricks or blocks directly from a mixture of raw materials.

- Extrusion Process: Utilizes an extrusion process where the raw material mixture, usually a combination of cement, aggregates (such as sand or gravel), and water, is fed into the machine.

- Compression and Shaping: The machine compresses and shapes the material into bricks or blocks of uniform size and shape as it moves through the extrusion chamber.

2. Key Components:

- Hopper: Receives and stores the raw material mixture before it enters the extrusion chamber.

- Extrusion Chamber: Where the raw material is compressed and shaped into bricks or blocks.

- Cutting Mechanism: Cuts the extruded material into individual bricks or blocks of desired dimensions.

- Conveyor System: Transports the finished bricks or blocks away from the machine for curing or further processing.

3. Automation and Control:

- Automatic Operation: Operates automatically once the raw material mixture is loaded into the hopper and the machine is started.

- Control Panel: Includes a control panel for setting parameters such as extrusion speed, cutting dimensions, and production rate.

4. Advantages:

- Efficiency: Automates the brick or block production process, reducing labor costs and increasing production efficiency.

- Consistency: Produces bricks or blocks of consistent size, shape, and quality.

- Versatility: Can produce various types of bricks or blocks depending on the raw material mixture and machine settings.

- Environmental Benefits: Often designed to minimize waste and optimize material usage, contributing to sustainability efforts.

5. Applications:

- Construction Industry: Used in the construction of residential, commercial, and industrial buildings for walls, partitions, and structural elements.

- Infrastructure Projects: Provides building materials for roads, bridges, and other infrastructure projects requiring durable and uniform bricks or blocks.

6. Maintenance and Safety:

- Regular Maintenance: Requires regular maintenance to ensure optimal performance and longevity of components.

- Safety Features: Includes safety mechanisms such as emergency stop buttons and safety guards to protect operators and prevent accidents.

7. Size and Capacity:

- Size: Available in various sizes and configurations to accommodate different production capacities and space constraints.

- Output: Production capacity varies depending on the machine model and specifications, ranging from hundreds to thousands of bricks or blocks per day.

An Automatic Brick Free Machine represents a modern approach to brick and block production, offering efficiency, consistency, and versatility in meeting the demands of construction projects. Its automation capabilities streamline the manufacturing process while maintaining high standards of quality and reliability.