Functions and Benefits of Nonferrous Metal Sorting System

2024-07-23

A nonferrous metal sorting system is designed to separate and classify nonferrous metals from other materials and from each other. Nonferrous metals, which include aluminum, copper, lead, nickel, and zinc, do not contain significant amounts of iron and are not magnetic. These systems are crucial in recycling and waste management industries for efficiently processing scrap metal and ensuring valuable materials are properly recovered.

Key Features:

1. Technology:

- Eddy Current Separation: Utilizes an eddy current separator that generates a magnetic field to repel nonferrous metals and separate them from other materials.

- Optical Sorting: Employs advanced cameras and sensors to identify and sort metals based on color, shape, and other properties.

- X-Ray Fluorescence (XRF): Analyzes the metal composition to accurately sort and classify different types of nonferrous metals.

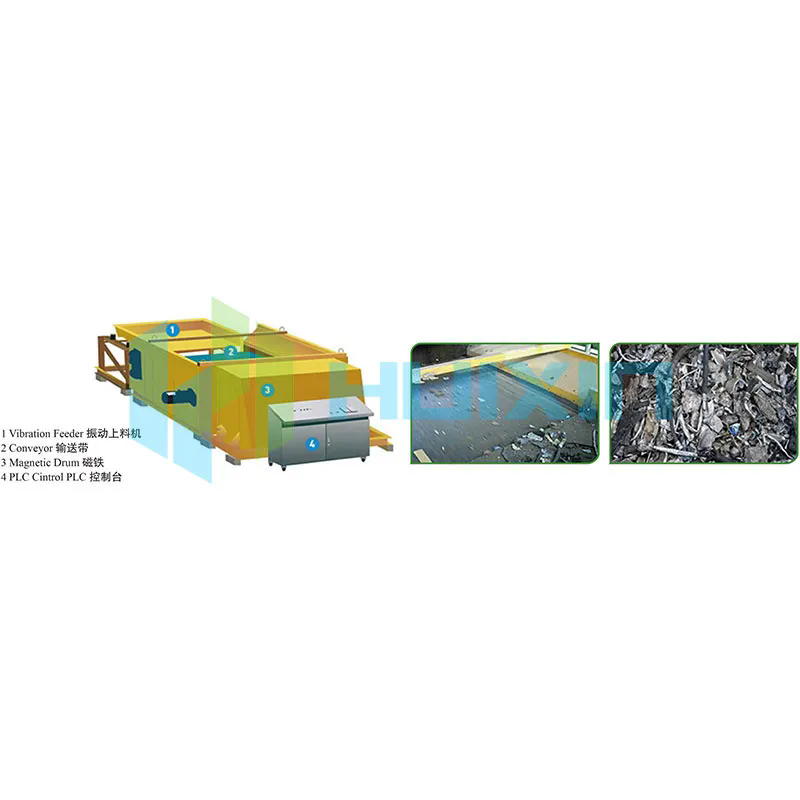

2. Components:

- Conveyors: Transport materials through the sorting system and to various processing stages.

- Hoppers and Feeders: Distribute and feed materials into the sorting system.

- Separators: Different types of separators (e.g., magnetic, air, or vibration-based) used to segregate nonferrous metals from other materials.

- Control Systems: Advanced control panels and software manage the sorting process, optimizing efficiency and accuracy.

3. Types:

- Manual Sorting Systems: Require human operators to manually sort metals, often used in smaller or less automated operations.

- Automated Sorting Systems: Use advanced technologies for fully automated sorting, suitable for large-scale operations and high throughput.

Functions:

1. Metal Recovery:

- Efficient Sorting: Separates nonferrous metals from other waste materials, ensuring valuable metals are recovered and recycled.

- Purity: Achieves high levels of purity in sorted metals, which is important for recycling and resale.

2. Waste Management:

- Reduction of Landfill: Helps reduce the amount of nonferrous metals that end up in landfills by ensuring they are properly recycled.

- Resource Conservation: Promotes the recycling of nonferrous metals, conserving natural resources and reducing environmental impact.

3. Economic Benefits:

- Revenue Generation: Enables the recovery of valuable metals that can be sold or reused, providing economic benefits to recycling facilities.

- Cost Savings: Reduces the cost of waste disposal by maximizing the recovery of valuable materials.

Benefits:

1. Accuracy:

- High Precision: Advanced technologies provide accurate sorting of nonferrous metals, ensuring high-quality recovered materials.

- Customizable: Systems can be customized to handle various types of nonferrous metals and specific sorting requirements.

2. Efficiency:

- Increased Throughput: Automated systems handle large volumes of material quickly and efficiently.

- Reduced Labor Costs: Automated sorting reduces the need for manual labor, lowering operational costs.

3. Environmental Impact:

- Recycling: Facilitates the recycling of nonferrous metals, reducing environmental impact and conserving resources.

- Waste Reduction: Helps in the effective management of waste and minimizes landfill use.

4. Safety:

- Reduced Manual Handling: Minimizes the need for manual sorting, reducing the risk of injury and improving workplace safety.

Applications:

1. Recycling Facilities:

- Scrap Metal Processing: Used in recycling centers to process and sort scrap metal for recycling.

- Electronics Recycling: Helps recover nonferrous metals from electronic waste (e-waste).

2. Manufacturing:

- Material Recovery: Used in manufacturing processes to recover and recycle nonferrous metals from production waste.

3. Waste Management:

- Municipal Waste: Integrated into municipal waste management systems to sort and recover valuable metals from general waste.

4. Mining and Extraction:

- Post-Mining Processing: Used to process and sort nonferrous metals extracted during mining operations.

Maintenance Tips:

1. Regular Inspection:

- Check Components: Regularly inspect and maintain key components, such as conveyors, separators, and control systems, to ensure optimal performance.

2. Cleaning:

- Remove Debris: Keep the sorting system clean and free of debris to prevent malfunctions and maintain efficiency.

3. Calibration:

- Adjust Settings: Regularly calibrate sorting equipment to ensure accurate metal detection and separation.

4. Safety Checks:

- Monitor Systems: Implement safety checks and protocols to prevent accidents and ensure the system operates safely.

Conclusion:

A nonferrous metal sorting system is essential for efficient metal recovery and recycling, utilizing advanced technologies to separate and classify valuable nonferrous metals from waste materials. Its benefits include improved accuracy, efficiency, and environmental impact, making it a critical component in recycling and waste management operations. Regular maintenance and proper handling ensure the system remains effective and continues to provide economic and environmental advantages.