Information about Parallel Grinding Wheels

2024-07-28

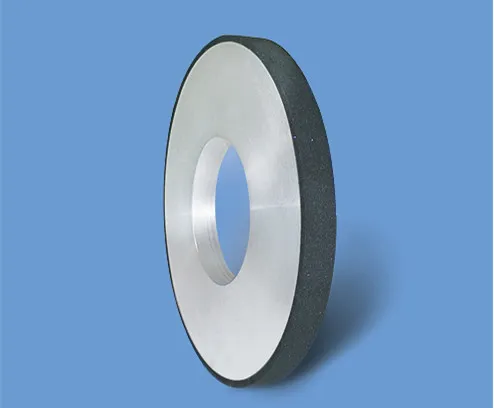

A parallel grinding wheel is a type of abrasive tool used in precision grinding applications where parallel surfaces need to be ground or finished. The term "parallel" refers to the wheel's ability to grind two parallel surfaces simultaneously or maintain parallelism in the grinding process. Here’s an overview of parallel grinding wheels:

Key Features:

1. Design:

- Parallel Surfaces: Typically features a flat, parallel surface design which is ideal for grinding applications that require maintaining parallelism between two surfaces.

- Shape: Often found in configurations such as flat wheels or disc wheels, designed to ensure even contact with the workpiece.

2. Construction:

- Abrasive Material: Made from various abrasive materials including aluminum oxide, silicon carbide, or cubic boron nitride (CBN), depending on the material being ground and the required finish.

- Bonding: The abrasive grains are bonded to the wheel using a binding material such as vitrified, resin, or metal bond, which determines the wheel’s hardness and durability.

3. Applications:

- Precision Grinding: Used in precision grinding operations where achieving a high level of parallelism and flatness is essential.

- Surface Finishing: Suitable for finishing applications where a smooth and parallel surface is required.

4. Mounting and Usage:

- Mounting: Typically mounted on a grinding machine using a central arbor or spindle.

- Operation: The wheel is used in grinding machines like surface grinders, tool and cutter grinders, or cylindrical grinders to process the workpiece.

Applications:

1. Manufacturing:

- Metalworking: Used in metalworking industries to grind parallel surfaces on metal parts and components.

- Tool Grinding: Ideal for sharpening and finishing cutting tools where parallelism is critical.

2. Precision Engineering:

- Machine Components: Employed to achieve precise parallel surfaces on machine components and assemblies.

- Optics and Precision Parts: Used in the production of optical components and other high-precision parts where surface flatness is crucial.

3. Automotive:

- Engine Parts: Utilized in automotive manufacturing to grind parallel surfaces on engine components and other critical parts.

Benefits:

1. Precision: Provides high precision in grinding operations, ensuring that parallel surfaces are achieved consistently.

2. Surface Finish: Capable of delivering a smooth and even surface finish, reducing the need for additional finishing processes.

3. Versatility: Can be used on a variety of materials, including metals, ceramics, and composites, depending on the abrasive material used.

Selection:

1. Abrasive Material:

- Material Compatibility: Choose the abrasive material based on the workpiece material and the desired surface finish.

- Hardness: Select a wheel with the appropriate hardness to balance cutting efficiency and wheel life.

2. Bonding Type:

- Vitrified Bond: Provides a rigid and durable bond, suitable for heavy-duty grinding applications.

- Resin Bond: Offers a more flexible bond, ideal for achieving a finer finish and reducing heat generation.

- Metal Bond: Used for very hard materials and high-precision grinding.

3. Size and Shape:

- Wheel Size: Ensure the wheel size matches the specifications of your grinding machine and the requirements of the grinding task.

- Shape and Profile: Choose the shape and profile of the wheel based on the specific grinding application and workpiece geometry.

Maintenance:

1. Dressing:

- Wheel Dressing: Regularly dress the grinding wheel to maintain its cutting performance and ensure consistent surface finishes.

- Truing: Ensure the wheel remains true and balanced to prevent vibration and achieve accurate grinding.

2. Inspection:

- Wear and Damage: Inspect the wheel for signs of wear, cracks, or other damage before use. Replace the wheel if it shows significant signs of wear or damage.

3. Cooling:

- Coolant Use: Use appropriate coolant or grinding fluid to reduce heat generation and improve the grinding process.

Parallel grinding wheels are essential tools for achieving high precision and surface quality in various grinding applications. Their design and construction make them suitable for tasks that require maintaining parallelism and achieving smooth finishes.