Key points regarding the V8 plate heat exchanger gasket

2024-01-05

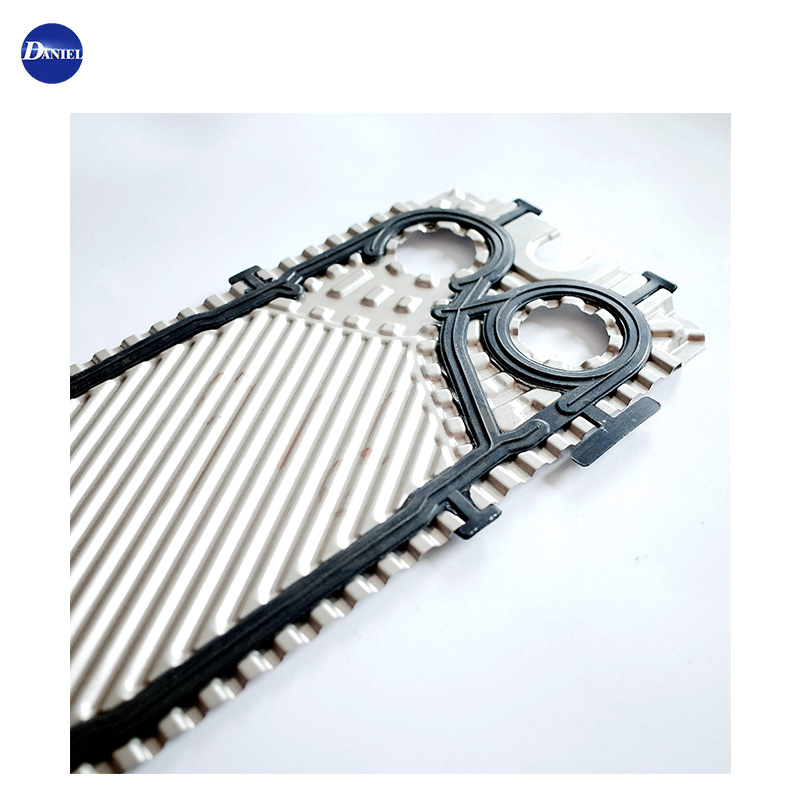

A V8 plate heat exchanger gasket refers to the gasket used in a plate heat exchanger with a V8 arrangement of plates. Plate heat exchangers are devices used for transferring heat between two fluid streams through a series of metal plates with a gasket in between. The V8 arrangement suggests that the plates are stacked in a specific pattern, possibly resembling the shape of the letter "V" with 8 plates forming the structure.

Here are some key points regarding the V8 plate heat exchanger gasket:

1. Material: The gasket used in a V8 plate heat exchanger is typically made of a flexible and durable material, such as rubber or synthetic elastomers. The choice of material depends on the compatibility with the fluids being processed and the temperature and pressure conditions.

2. Sealing Function: The primary function of the gasket is to create a tight seal between adjacent plates, preventing the mixing of the two fluid streams and ensuring efficient heat transfer. The gasket should be designed to withstand the operating conditions of the heat exchanger.

3. Gasket Design: The design of the gasket is crucial for maintaining the integrity of the seal. It should have the appropriate thickness, shape, and dimensions to fit the V8 arrangement of plates securely.

4. Heat and Chemical Resistance: The gasket must be resistant to the temperatures and chemical properties of the fluids flowing through the heat exchanger. This is essential for preventing degradation and maintaining the effectiveness of the seal over time.

5. Replacement and Maintenance: Gaskets in plate heat exchangers may need replacement over time due to wear, aging, or damage. Proper maintenance involves checking the condition of gaskets regularly and replacing them when necessary to prevent leaks and ensure efficient heat transfer.

6. Manufacturer Specifications: It is important to use gaskets that meet the specifications provided by the heat exchanger manufacturer. Using gaskets that are not designed for the specific plate arrangement and operating conditions can lead to performance issues and potential leaks.

7. Installation Considerations: Proper installation of the gaskets is critical for the effective functioning of the plate heat exchanger. This includes ensuring correct alignment, tightening bolts to the recommended torque, and following the manufacturer's guidelines.

When considering replacement gaskets for a V8 plate heat exchanger, it's advisable to consult the original equipment manufacturer (OEM) or a reputable supplier to ensure compatibility and adherence to quality standards. Additionally, maintaining a record of the gasket material, dimensions, and specifications can assist in obtaining suitable replacements when needed.