Laminated Building Formwork: The Future of Efficient Construction

2024-09-18

In the construction industry, the choice of materials directly influences the quality, speed, and cost-effectiveness of a project. One such material that has gained widespread popularity in recent years is laminated building formwork. Known for its durability, reusability, and cost savings, laminated formwork is a game changer, especially in concrete-based projects.

In this blog, we will explore the benefits, uses, and advantages of laminated building formwork, and why it is becoming a preferred choice for modern construction.

What is Laminated Building Formwork?

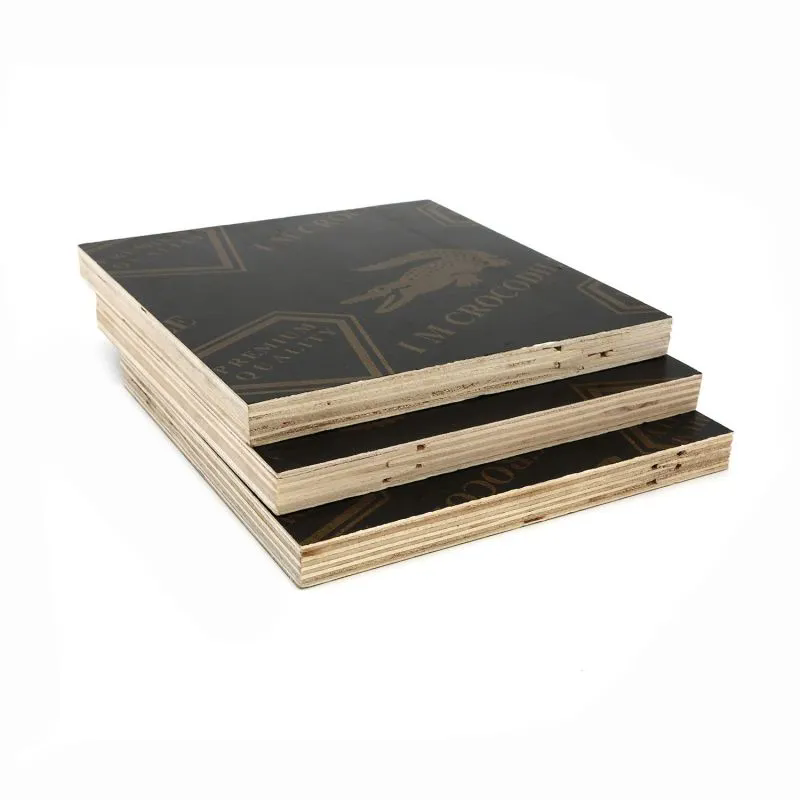

Laminated building formwork is a type of formwork made from layers of wood veneer, pressed and bonded together with strong adhesives under high pressure and heat. This manufacturing process results in a durable, smooth, and water-resistant product that can withstand the rigors of construction work. The outer layers are often coated with a phenolic or melamine film, which enhances its resistance to moisture and ensures a smooth finish on the poured concrete surface.

Laminated formwork is commonly used in projects where repeated use is required, as it offers a high level of durability and maintains its shape and structural integrity over multiple uses.

Advantages of Laminated Building Formwork

1. Durability and Strength

Laminated building formwork is known for its exceptional durability. The multi-layered construction gives it high structural strength, enabling it to withstand the pressure and weight of wet concrete without warping or bending. This strength also makes it suitable for high-load applications, such as large walls, columns, and slabs.

Additionally, the lamination process ensures that the formwork is more resistant to environmental factors such as humidity, temperature fluctuations, and exposure to water, making it a reliable choice in various construction environments.

2. Smooth Concrete Finish

The smooth surface of laminated formwork ensures a high-quality finish on the concrete surface. The top layer is typically coated with a film that provides a smooth, non-stick surface, making it easy to remove once the concrete has cured. This reduces the need for extensive post-pour finishing work, saving time and labor costs.

In projects where the appearance of the concrete surface is important, such as in architectural or decorative concrete applications, laminated formwork is an excellent choice.

3. Reusability

One of the biggest advantages of laminated building formwork is its reusability. Traditional wooden formwork often deteriorates quickly due to exposure to moisture and repeated use, leading to higher material costs over the course of a project. Laminated formwork, on the other hand, can be reused multiple times without losing its structural integrity or smooth surface finish.

In fact, laminated formwork can often be reused 20 to 30 times or more, depending on the quality of the material and the conditions of use. This makes it a cost-effective option for large-scale projects where formwork is used repeatedly.

4. Water and Weather Resistance

The laminated construction and surface coating of the formwork make it resistant to water, a key factor in ensuring longevity, especially when exposed to wet concrete or outdoor elements. This water resistance also prevents swelling and warping, which are common issues with traditional wooden formwork.

In addition to its water resistance, laminated formwork performs well in a variety of weather conditions, including high humidity and temperature variations. This makes it a reliable option for both indoor and outdoor construction projects.

5. Cost-Effectiveness

While the initial cost of laminated building formwork may be higher than traditional wooden formwork, its durability and reusability make it a more cost-effective solution in the long run. The ability to use the same formwork over multiple pours significantly reduces the need for purchasing new materials, lowering the overall formwork cost per cycle.

Moreover, the smooth surface reduces labor costs associated with cleaning, repairing, and refinishing the formwork, further contributing to cost savings throughout the project.

6. Eco-Friendly Option

Laminated building formwork is an eco-friendly alternative to disposable wooden formwork. Its reusability reduces waste generated on construction sites, and many manufacturers produce laminated formwork from sustainably sourced wood, contributing to responsible forest management. By choosing reusable, laminated options, construction companies can reduce their environmental impact and work towards more sustainable building practices.

Common Applications of Laminated Building Formwork

Laminated building formwork is widely used across various types of construction projects, including:

- Residential and Commercial Buildings: For walls, slabs, and columns where a smooth concrete finish is desired.

- Bridges and Infrastructure: For large concrete pours that require formwork with high strength and durability.

- Architectural Concrete: Where the appearance of exposed concrete is an important design element, laminated formwork provides a smooth finish that enhances the aesthetic appeal.

- Industrial Facilities: For large-scale concrete structures in factories and warehouses.

Tips for Proper Use and Maintenance

To maximize the lifespan and performance of laminated building formwork, it’s essential to follow some best practices:

1. Proper Cleaning: After each use, the formwork should be cleaned thoroughly to remove any concrete residue. This helps maintain the smooth surface for future pours.

2. Storage: When not in use, laminated formwork should be stored in a dry, covered area to prevent unnecessary exposure to the elements, which could shorten its lifespan.

3. Handle with Care: Avoid dropping or damaging the formwork during transportation and handling, as cracks or dents can compromise its integrity.

4. Regular Inspection: Before each use, inspect the formwork for any signs of damage, such as cracks, chips, or surface wear. Damaged formwork should be repaired or replaced to ensure a smooth and safe pour.

Conclusion

Laminated building formwork is an innovative and highly efficient material that offers multiple advantages for modern construction projects. From its durability and smooth finish to its reusability and cost-effectiveness, it is an ideal choice for contractors looking to enhance productivity while reducing material waste and labor costs.

As the construction industry continues to evolve, the adoption of high-performance materials like laminated formwork will play a key role in building structures that are not only strong and aesthetically pleasing but also sustainable. Whether you’re working on a large-scale infrastructure project or a residential development, laminated building formwork is a smart investment that delivers long-term value.