Precision Components: The Cornerstone of Modern Engineering and Manufacturing

2025-01-24

In today’s world of advanced technology and engineering, precision components have become the backbone of countless industries. From aerospace to automotive, medical devices to electronics, and beyond, precision components play an essential role in ensuring the accuracy, reliability, and functionality of complex systems.

But what exactly are precision components? Why are they so crucial in modern manufacturing? And how do they contribute to innovation and efficiency? Let’s dive into the world of precision components and uncover the answers.

What Are Precision Components?

Precision components are mechanical parts or assemblies that are manufactured with extremely tight tolerances to meet exact specifications. These components are crafted using advanced techniques and tools, ensuring that every dimension, angle, and surface finish aligns with design requirements.

Precision components can include gears, bearings, shafts, fasteners, housings, connectors, and a wide array of custom-machined parts. Their defining characteristic is their accuracy, which ensures seamless integration and operation within larger assemblies.

Why Precision Components Matter

Precision components are critical because they ensure that machinery and systems function efficiently and reliably. A minor error in the dimensions of a component can lead to performance issues, inefficiencies, or even system failure. Here are some key reasons why precision components are indispensable:

1. Accuracy and Reliability

Precision components are manufactured to exact measurements, ensuring accurate fits and reliable operation. This is particularly important in industries such as aerospace and medical devices, where even the slightest deviation can have serious consequences.

2. Improved Performance

In mechanical systems, precision components reduce friction, vibration, and wear, leading to improved efficiency and performance. For instance, precision gears in automotive transmissions contribute to smoother and more energy-efficient operation.

3. Longevity of Systems

High-quality precision components are made from durable materials and undergo meticulous manufacturing processes. This ensures they withstand stress, minimize wear, and extend the lifespan of the systems they are part of.

4. Compatibility

Precision components are designed to integrate seamlessly into existing systems. Their exact specifications allow for compatibility across different systems and applications, reducing the need for extensive modifications or adjustments.

Industries That Rely on Precision Components

Precision components are ubiquitous, with applications across a broad range of industries. Some of the sectors that rely heavily on these components include:

1. Aerospace

The aerospace industry requires precision components to ensure the safety and efficiency of aircraft and spacecraft. From turbine blades to navigation systems, every component must meet stringent quality standards to withstand extreme conditions.

2. Automotive

In the automotive sector, precision components like gears, bearings, and fuel injectors contribute to the performance, safety, and fuel efficiency of vehicles. Modern vehicles, especially electric and autonomous cars, depend on precision engineering for advanced functionality.

3. Medical Devices

Medical devices, such as surgical instruments, implants, and diagnostic equipment, rely on precision components for accuracy and reliability. These components ensure the proper functioning of life-saving equipment and contribute to patient safety.

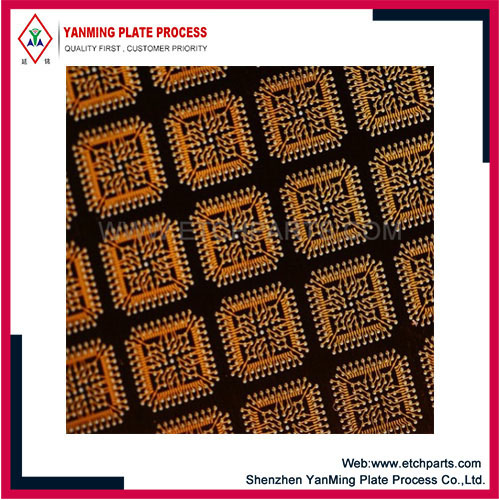

4. Electronics

In the electronics industry, tiny precision components like connectors, microchips, and sensors are crucial for the performance of devices such as smartphones, laptops, and wearable technology.

5. Industrial Machinery

Precision components are integral to the smooth operation of industrial equipment and machinery. They enhance productivity, reduce downtime, and ensure consistent quality in manufacturing processes.

The Manufacturing of Precision Components

The production of precision components involves advanced techniques, state-of-the-art machinery, and strict quality control measures. Here are some of the processes commonly used:

1. CNC Machining

Computer Numerical Control (CNC) machining is one of the most popular methods for manufacturing precision components. It uses computer-controlled tools to cut, shape, and finish materials with incredible accuracy.

2. Injection Molding

For plastic precision components, injection molding is often employed. This process allows for the mass production of identical parts with tight tolerances and excellent surface finishes.

3. Casting and Forging

For larger or more complex components, casting and forging techniques are used. These methods produce strong, durable parts that can be further refined to meet precision requirements.

4. Additive Manufacturing

Additive manufacturing, or 3D printing, has revolutionized the production of precision components. This technology enables rapid prototyping and the creation of complex geometries with minimal material waste.

5. Surface Finishing

Surface finishing techniques, such as polishing, plating, and coating, enhance the performance and appearance of precision components. They also improve corrosion resistance and wear properties.

Trends and Innovations in Precision Components

The demand for precision components continues to grow as industries push the boundaries of innovation. Here are some trends shaping the future of this field:

1. Miniaturization

As devices become smaller and more compact, there is an increasing need for miniaturized precision components. This is especially true in electronics, medical devices, and robotics.

2. Advanced Materials

The development of advanced materials, such as carbon composites, titanium alloys, and ceramics, is expanding the capabilities of precision components. These materials offer superior strength, lightweight properties, and resistance to extreme conditions.

3. Automation and AI

Automation and artificial intelligence are enhancing the manufacturing processes for precision components. Smart systems can monitor production in real-time, detect defects, and ensure consistent quality.

4. Sustainability

Sustainability is becoming a priority in the manufacturing of precision components. Techniques such as additive manufacturing and material recycling are reducing waste and minimizing the environmental impact of production.

Conclusion

Precision components are the foundation of modern engineering and manufacturing, enabling the creation of systems that are accurate, efficient, and reliable. From the smallest electronic connectors to the largest industrial gears, these components are essential in shaping the technology and infrastructure of today’s world.

As industries evolve and new challenges emerge, the demand for innovative and high-quality precision components will only continue to grow. By embracing advanced manufacturing techniques, cutting-edge materials, and sustainable practices, manufacturers can continue to deliver precision components that drive progress and success across every sector.