The Essential Guide to Anti-Static PFA Tubes: A Key Component in Modern Industries

2024-09-04

In the realm of precision and cleanliness, anti-static PFA tubes have become indispensable across various industries. Whether you’re working in semiconductor manufacturing, pharmaceuticals, or any field that requires the handling of sensitive materials, these tubes offer a blend of protection and performance. In this blog, we’ll delve into what anti-static PFA tubes are, their key features and benefits, and their applications across different industries.

What Are Anti-Static PFA Tubes?

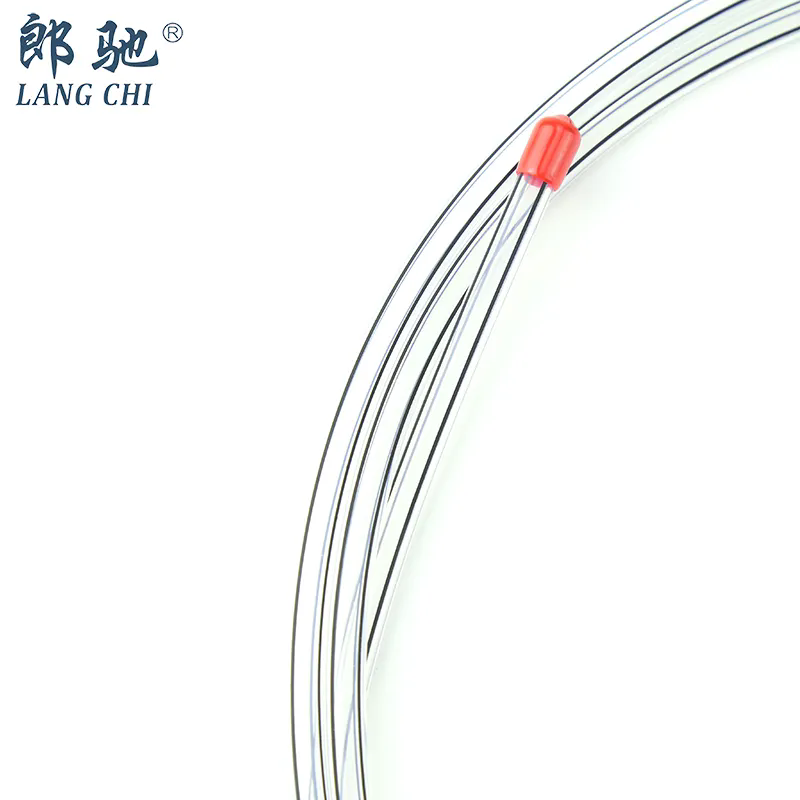

Anti-static PFA tubes are specialized tubes made from Perfluoroalkoxy (PFA) resin that are designed to prevent the buildup of static electricity. PFA is a type of fluoropolymer known for its excellent chemical resistance and thermal stability. By incorporating anti-static properties, these tubes are engineered to handle sensitive applications where static electricity could pose a risk.

Key Features of Anti-Static PFA Tubes

1. Anti-Static Properties

The primary feature of anti-static PFA tubes is their ability to resist static electricity buildup. This property is crucial in environments where static charges can lead to contamination, damage to sensitive components, or unsafe conditions. Anti-static PFA tubes ensure that static electricity is effectively dissipated, minimizing the risk of electrostatic discharge (ESD).

2. Chemical Resistance

PFA tubes are renowned for their superior chemical resistance. They can withstand exposure to a wide range of chemicals, including acids, bases, and solvents, without degrading or compromising their structural integrity. This makes them ideal for use in environments where harsh chemicals are handled.

3. High Temperature Tolerance

PFA has excellent thermal stability, allowing these tubes to operate effectively at high temperatures. They can handle temperatures up to 260°C (500°F) without losing their properties, making them suitable for applications that involve heat.

4. Transparency

Anti-static PFA tubes are typically transparent, allowing for easy monitoring of the flow of materials within the tube. This visibility is useful in applications where it is important to observe the contents or ensure proper flow.

5. Flexibility and Durability

PFA tubes are flexible and resistant to cracking or breaking, even under stress. This flexibility allows them to be easily bent or shaped to fit specific applications, while their durability ensures a long service life.

Benefits of Using Anti-Static PFA Tubes

1. Enhanced Safety

By preventing static electricity buildup, anti-static PFA tubes enhance safety in environments where static discharge could lead to explosions, fires, or damage to sensitive equipment. This is particularly important in industries like semiconductor manufacturing, where static can affect electronic components.

2. Improved Product Quality

In industries such as pharmaceuticals and biotechnology, maintaining a contamination-free environment is crucial. Anti-static PFA tubes help prevent contamination from static charges, ensuring that products remain pure and high-quality.

3. Extended Equipment Life

The chemical resistance and durability of PFA tubes contribute to the longevity of equipment. By protecting against chemical corrosion and physical damage, these tubes can reduce maintenance costs and extend the life of associated machinery.

4. Operational Efficiency

The transparency and flexibility of anti-static PFA tubes facilitate smooth operation in various applications. The ability to monitor material flow and adapt the tube to different configurations enhances overall efficiency and ease of use.

5. Compliance with Standards

Anti-static PFA tubes often meet industry standards and regulations for cleanliness and safety. Using these tubes can help ensure compliance with stringent requirements, particularly in regulated industries like pharmaceuticals and electronics.

Applications of Anti-Static PFA Tubes

1. Semiconductor Manufacturing

In semiconductor manufacturing, the control of static electricity is critical to prevent damage to sensitive electronic components. Anti-static PFA tubes are used in various processes, including the transport of chemicals and gases, to ensure a static-free environment.

2. Pharmaceuticals and Biotechnology

In the pharmaceutical and biotechnology industries, maintaining a contamination-free environment is essential. Anti-static PFA tubes are used in processes involving the transfer of liquids and gases to prevent static-induced contamination and ensure product purity.

3. Chemical Processing

The chemical resistance of PFA tubes makes them suitable for use in chemical processing applications. They are used to transport and handle corrosive chemicals, solvents, and acids without degrading or contaminating the contents.

4. Food and Beverage Industry

In the food and beverage industry, anti-static PFA tubes are used in processes where contamination must be avoided. Their chemical resistance and ability to prevent static buildup make them ideal for handling ingredients and ensuring product quality.

5. Medical and Laboratory Applications

In medical and laboratory settings, anti-static PFA tubes are used for the transfer and handling of sensitive materials. Their anti-static properties and chemical resistance make them suitable for use in various experimental and analytical processes.

Choosing the Right Anti-Static PFA Tube

When selecting anti-static PFA tubes for your application, consider the following factors:

1. Tube Diameter and Length: Choose a tube with the appropriate diameter and length for your specific needs. Ensure it fits the equipment or system where it will be used.

2. Chemical Compatibility: Verify that the PFA tube is compatible with the chemicals it will come into contact with. This ensures that the tube will maintain its integrity and performance.

3. Temperature Range: Ensure the tube can handle the temperatures involved in your application. PFA tubes typically tolerate high temperatures, but it’s important to confirm this for your specific use case.

4. Anti-Static Properties: Confirm that the tube has the necessary anti-static properties to meet your requirements. This is crucial for preventing static electricity buildup and ensuring a safe and effective operation.

5. Compliance with Standards: Check if the tube meets industry standards and regulations relevant to your application, particularly in regulated industries.

Conclusion

Anti-static PFA tubes are a critical component in industries where static electricity and chemical exposure pose significant risks. Their combination of anti-static properties, chemical resistance, high temperature tolerance, and flexibility makes them an ideal choice for a wide range of applications. By understanding their features, benefits, and applications, you can make informed decisions and select the right PFA tubes to enhance safety, product quality, and operational efficiency in your industry. Embrace the advantages of anti-static PFA tubes and ensure a reliable and effective solution for your sensitive material handling needs.