The Ultimate Guide to Auto Bender Machines

2025-04-03

Auto bender machines have revolutionized the die-making and metal bending industries, offering precision, efficiency, and automation. These machines are widely used in packaging, printing, and manufacturing industries to create high-quality cutting dies, metal plates, and other custom-formed components. In this blog, we will explore the benefits, applications, and key features of auto bender machines, helping you understand their role in modern production processes.

What Is an Auto Bender Machine?

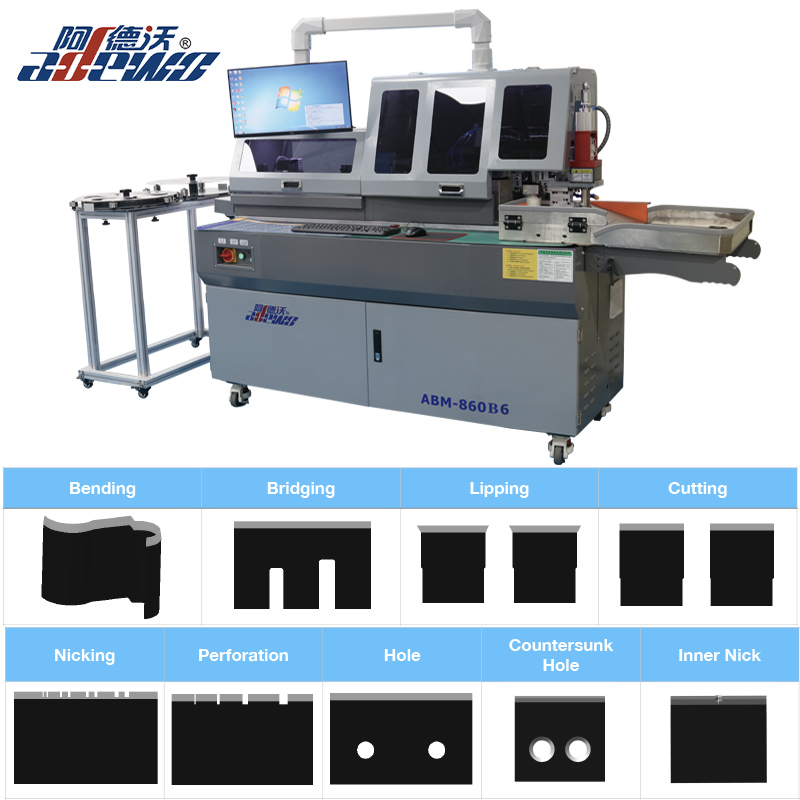

An auto bender machine is a computer-controlled device designed to automatically bend, cut, and shape metal strips, primarily for die-making and sheet metal applications. It eliminates the need for manual bending, reducing labor costs and improving precision. These machines use advanced software to program complex shapes and designs, making them essential for industries that require intricate bending work.

Benefits of Using an Auto Bender Machine

1. High Precision and Accuracy

Auto bender machines use advanced CNC (Computer Numerical Control) technology to achieve precise bends and cuts. This ensures consistency in production, reducing errors and material wastage.

2. Increased Production Efficiency

With automation, these machines can process multiple bends quickly, significantly reducing production time compared to manual bending. This allows businesses to meet high-demand requirements efficiently.

3. Reduced Labor Costs

Since the machine automates the bending process, fewer operators are required to handle production. This minimizes human error and labor expenses while increasing output.

4. Versatility in Applications

Auto bender machines can handle a variety of materials, including stainless steel, aluminum, and carbon steel. They are used in multiple industries, including packaging, die-cutting, signage, and metal fabrication.

5. Consistent Quality

Automation ensures that every piece produced is identical, maintaining high quality and precision across large production runs. This is especially important for industries that require detailed and complex designs.

Common Applications of Auto Bender Machines

1. Die-Making for Packaging and Printing

One of the primary uses of auto bender machines is in the creation of steel rule dies for cutting paper, cardboard, and other packaging materials. The precision bending ensures accurate and durable dies.

2. Metal Fabrication and Sheet Bending

In the manufacturing industry, auto bender machines shape metal components for various applications, including construction, machinery, and automotive parts.

3. Signage and Advertising

The ability to bend and cut metal accurately makes auto bender machines ideal for producing metal letters, logos, and other signage components for commercial and industrial use.

4. Electronics and Appliance Manufacturing

Auto bender machines assist in forming metal casings, brackets, and frames used in electronic devices and household appliances. Their high precision ensures compatibility and durability in assembled products.

Key Features to Look for in an Auto Bender Machine

1. CNC Control System

A high-quality CNC system enables precise programming and automation, allowing for intricate designs and high-speed production.

2. Compatibility with Different Materials

Choose a machine that can handle various metals such as stainless steel, aluminum, and carbon steel, ensuring versatility for different projects.

3. Bending and Cutting Capabilities

A good auto bender machine should have advanced bending, notching, cutting, and perforating functions to create complex shapes efficiently.

4. User-Friendly Software

Look for a machine with intuitive software that allows for easy programming and modification of designs. Compatibility with common design software is a plus.

5. Durability and Low Maintenance

A robust machine with high-quality components ensures long-lasting performance and minimal downtime for repairs or maintenance.

Conclusion

Auto bender machines have transformed the way metal bending and die-making industries operate. Their automation, precision, and efficiency make them an invaluable tool for businesses seeking to improve production speed and quality. Whether used for packaging, metal fabrication, or signage, these machines offer a cost-effective and reliable solution for achieving complex bends and cuts with minimal effort. By selecting the right machine with advanced features, businesses can enhance productivity and maintain a competitive edge in their industry.