Waterjet Parts: The Role of Ruby Orifices in Precision Cutting

2024-08-16

In the realm of waterjet cutting technology, precision and durability are paramount. One of the key components that ensures these qualities is the ruby orifice. Used in waterjet cutting systems, ruby orifices are critical for achieving accurate and efficient cutting performance. This blog will delve into what ruby orifices are, their benefits, applications, and how they contribute to the effectiveness of waterjet cutting systems.

1. What is a Ruby Orifice?

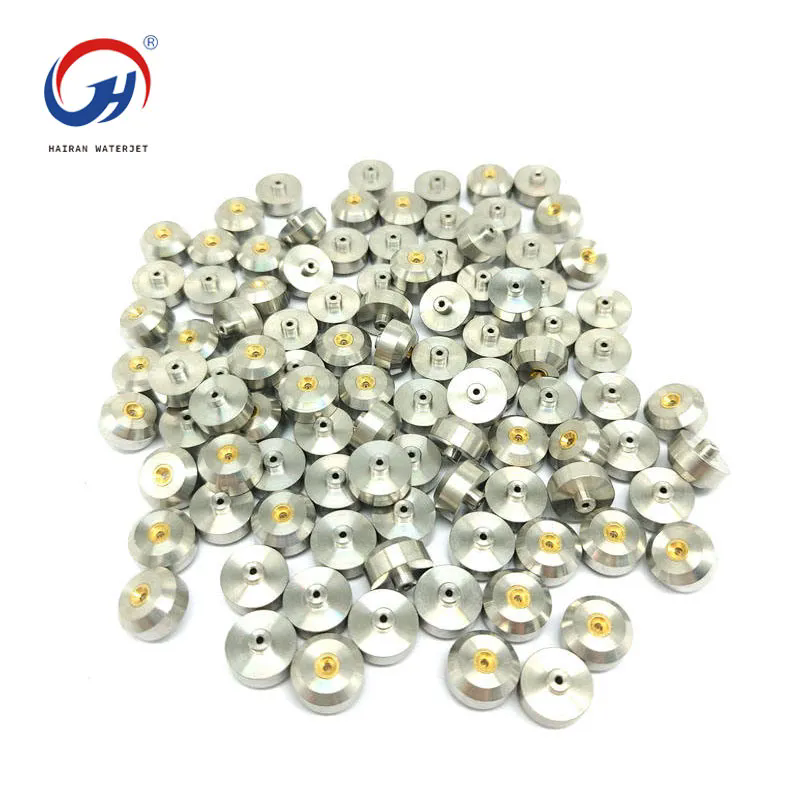

A ruby orifice is a specialized component used in waterjet cutting systems to control the flow of high-pressure water mixed with abrasives. The orifice is made from synthetic ruby, a highly durable material known for its hardness and resistance to wear.

Key Features of Ruby Orifices:

- Material: Synthetic ruby is chosen for its exceptional hardness and durability, which allows the orifice to withstand the abrasive nature of the cutting process and high-pressure water jets.

- Precision: The orifice is precisely manufactured to create a fine, controlled water jet that is crucial for achieving accurate cuts.

- Durability: Ruby’s hardness ensures that the orifice maintains its shape and functionality over time, reducing the need for frequent replacements.

2. Benefits of Ruby Orifices

Ruby orifices offer several benefits that enhance the performance of waterjet cutting systems:

- Enhanced Durability: Synthetic ruby is highly resistant to wear and erosion caused by abrasive materials. This durability extends the lifespan of the orifice and ensures consistent performance.

- Precision Cutting: The high precision of ruby orifices allows for fine, controlled waterjet streams. This is essential for achieving detailed and accurate cuts in a variety of materials.

- Consistent Performance: Ruby’s resistance to wear ensures that the orifice maintains its performance characteristics over time, leading to consistent cutting quality and reduced maintenance requirements.

- Reduced Downtime: The durability of ruby orifices translates to fewer replacements and less downtime, which can improve the overall efficiency of the cutting process.

- Cost-Effectiveness: Although ruby orifices may have a higher initial cost, their durability and longevity can result in cost savings over time due to reduced maintenance and replacement needs.

3. Applications of Ruby Orifices

Ruby orifices are used in various applications where precision and durability are crucial:

- Industrial Cutting: In manufacturing and fabrication industries, ruby orifices are employed to cut materials such as metals, composites, ceramics, and glass with high precision.

- Aerospace: The aerospace industry utilizes ruby orifices for cutting complex components from high-strength materials, where accuracy and reliability are critical.

- Automotive: Ruby orifices are used in automotive manufacturing for cutting and shaping parts, ensuring high-quality finishes and dimensional accuracy.

- Construction and Mining: In construction and mining, ruby orifices are employed to cut through tough materials, including rock and concrete, where durability and performance are essential.

- Art and Design: Artists and designers use waterjet cutting systems with ruby orifices to create intricate patterns and designs in various materials, achieving high levels of detail and precision.

4. Maintenance and Care of Ruby Orifices

To ensure the longevity and optimal performance of ruby orifices, proper maintenance and care are important:

- Regular Inspection: Periodically check the orifice for signs of wear or damage. Replace the orifice if it shows signs of significant wear to maintain cutting quality.

- Clean Environment: Keep the cutting environment clean to prevent the accumulation of debris and abrasives that could affect the orifice’s performance.

- Proper Handling: Handle ruby orifices with care to avoid physical damage. Use appropriate tools and techniques when installing or replacing the orifice.

- System Calibration: Ensure that the waterjet cutting system is properly calibrated to maintain optimal performance and extend the life of the orifice.

5. Future Trends and Innovations

The field of waterjet cutting and ruby orifices continues to evolve with advancements in technology and industry needs:

- Advanced Materials: Research is focused on developing new materials and coatings that enhance the durability and performance of orifices, potentially extending their lifespan even further.

- Improved Manufacturing Techniques: Advances in manufacturing technology aim to improve the precision and quality of ruby orifices, leading to better cutting performance and efficiency.

- Enhanced Automation: Integration of advanced automation and control systems in waterjet cutting machines can optimize the performance of ruby orifices and improve overall cutting accuracy.

- Sustainability: There is a growing emphasis on developing environmentally friendly materials and practices in the production and disposal of waterjet cutting components, including ruby orifices.

In conclusion, ruby orifices are a vital component in waterjet cutting systems, providing the precision and durability necessary for high-quality cutting performance. Their exceptional hardness and resistance to wear make them a preferred choice for a wide range of applications, from industrial manufacturing to artistic design. As technology advances, the role of ruby orifices will continue to evolve, offering even greater performance and efficiency in the world of waterjet cutting.