What Is PCB Assembly and How Does It Impact Modern Electronics?

2025-02-27

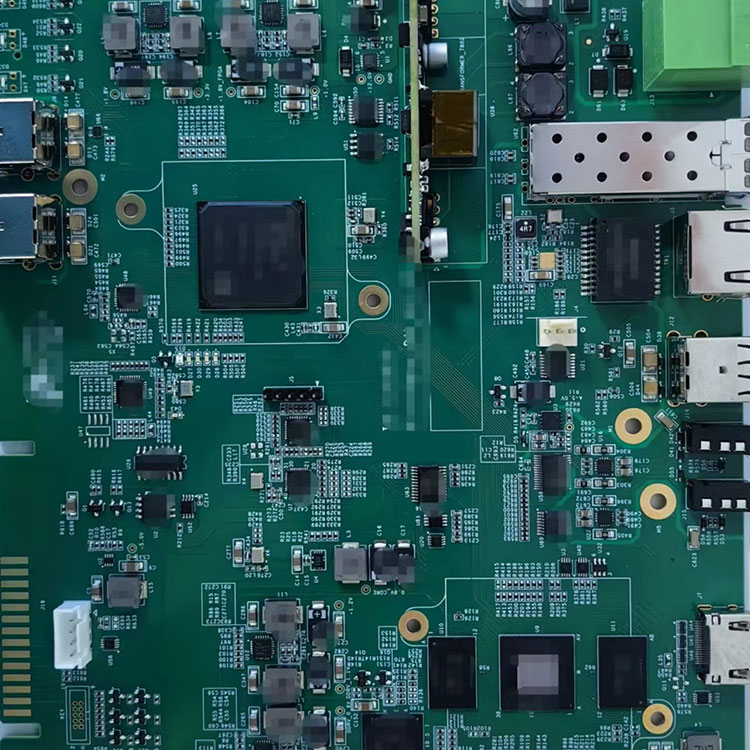

In today's world, almost every electronic device we use relies on a Printed Circuit Board (PCB) to function. From smartphones and computers to medical devices and industrial equipment, PCBs are integral components in the design of modern electronics. But what exactly is PCB assembly, and how does it impact the way we interact with technology every day? In this blog, we will explore the process of PCB assembly, the key components involved, and why it is so critical in the development of electronics.

What Is PCB Assembly?

PCB assembly (also known as PCBA) refers to the process of attaching electronic components onto a printed circuit board to create a functional electronic circuit. It is a crucial step in the manufacturing of almost every electronic device. The PCB itself provides the physical structure for the components and the pathways for electrical signals to flow between them.

The assembly process involves several stages, including component placement, soldering, and inspection. Each of these stages requires precision and accuracy to ensure that the final product performs reliably. PCB assembly can be performed using different techniques, depending on the complexity of the design and the components being used.

What Are the Key Stages in PCB Assembly?

1. Designing the PCB Layout

The first step in creating a PCB assembly is the design of the PCB layout. This step involves determining the size and shape of the board, as well as the placement of the various components. Engineers use software tools to create a schematic diagram that shows how all of the components will be connected.

The layout must be carefully planned to ensure that there is enough space for each component and that the electrical signals can flow without interference. The design also needs to take into account factors like heat dissipation, electrical noise, and manufacturability.

2. Component Placement

Once the PCB design is ready, the next step is to place the electronic components onto the board. This can be done manually for small batches or with automated machinery for large-scale production. The components include resistors, capacitors, integrated circuits (ICs), connectors, and other essential parts.

For automated placement, machines use pick-and-place technology, which involves picking up components from reels or trays and precisely placing them onto the board according to the design. This stage requires great accuracy, as the components need to be aligned properly to ensure proper functioning.

3. Soldering the Components

After the components are placed on the PCB, they must be soldered to the board to establish electrical connections. Soldering can be done in two primary ways: wave soldering and surface-mount soldering.

- Wave Soldering: This method is typically used for through-hole components, where the leads of the components pass through holes in the PCB. The PCB is passed over a wave of molten solder, which attaches the components to the board.

- Surface-Mount Soldering: This method is used for surface-mount devices (SMDs) that are placed directly on the surface of the PCB. The board is first coated with a thin layer of solder paste, and then it is placed in a reflow oven, where the paste melts and creates solder joints between the components and the PCB.

4. Inspection and Testing

Once the components are soldered to the PCB, the assembly must be inspected to ensure that the connections are solid and the components are in the correct locations. Various methods are used for inspection, including visual inspection, X-ray inspection, and automated optical inspection (AOI).

Testing is another critical step to ensure that the assembled PCB functions as intended. Electrical testing involves checking the continuity of the circuits, verifying the performance of components, and ensuring that there are no short circuits or open circuits. Functional testing may also be conducted to verify that the entire system operates as expected.

5. Final Assembly and Packaging

Once the PCB assembly has passed all inspections and tests, the final assembly is completed. This involves integrating the PCB into the final product, such as a smartphone, computer, or appliance. The assembled PCB is then packaged for shipment to customers or distributors.

Why Is PCB Assembly Important for Modern Electronics?

1. Miniaturization of Electronics

As consumer electronics become smaller and more compact, the demand for miniaturized PCBs has increased. PCB assembly allows manufacturers to create dense, high-performance boards that can house a large number of components in a small footprint. This is essential for creating sleek, portable devices like smartphones, wearables, and medical devices.

2. Reliability and Performance

The quality of the PCB assembly directly affects the reliability and performance of the final product. A well-assembled PCB ensures that all components are properly connected and function as intended. Poor soldering, incorrect component placement, or faulty connections can result in malfunctioning products, leading to costly recalls or repairs.

3. Cost Efficiency

Efficient PCB assembly can help reduce manufacturing costs. Automated assembly processes, such as pick-and-place machines and reflow ovens, allow for high-volume production at lower costs. By minimizing human error and improving the speed of the assembly process, manufacturers can produce high-quality PCBs at competitive prices.

4. Customizability

PCB assembly allows for a high degree of customization. Manufacturers can design PCBs with specific features and performance characteristics to meet the requirements of different industries. Whether it's a high-speed processor, a power management circuit, or a sensor module, PCB assembly enables the creation of specialized boards tailored to the needs of the application.

5. Support for Innovation

The advancements in PCB assembly technology have played a significant role in the rapid development of modern electronics. Innovations in component size, board design, and assembly techniques have enabled the creation of more advanced, powerful, and energy-efficient devices. PCB assembly supports the ongoing trend of technological innovation by providing the foundation for the latest electronic products.

Conclusion

PCB assembly is an essential process that powers the vast array of electronic devices we rely on today. From smartphones and laptops to medical equipment and industrial machinery, the role of PCB assembly cannot be overstated. It ensures that electronic components are properly connected, tested, and assembled into functional products that meet the high standards of performance, reliability, and safety. As electronics continue to evolve, PCB assembly will remain at the heart of innovation, driving the creation of smarter, more efficient technologies that shape our world.